How can you free up a sticky tranfer case actuator?

#41

Yes, don't lose the orientation of those magnets, or better yet, get another small magnet, mark one pole on it and test each of those from the top (the side you see looking down in the cap. Make sure that you get them attract-repel-attract-repel and more or less equally spaced. That one problem alone is enough to cause all your problems: not actuating, overheating, etc. As far as what to use, brake cleaner, emery cloth and JB Weld worked for me. You'll have to be patient and let it dry, you don't want to risk them falling off again.

The stator freewheeling in there- that sounds bad, but maybe the torque is so low due to the gear design that you barely feel it.

I'm all dosed up with Nyquil right now, so might fade out for a bit. I've been checking things often here as something to do without getting out of bed. Hopefully I'll be back at it before your JB Weld dries. I'm tempted to suggest something like dental floss with one knot tied around the springs so that it'll pull off easy once they are in, but give you enough to maybe pull it out of the black hole should the worst happen. Might just get in the way though.

The stator freewheeling in there- that sounds bad, but maybe the torque is so low due to the gear design that you barely feel it.

I'm all dosed up with Nyquil right now, so might fade out for a bit. I've been checking things often here as something to do without getting out of bed. Hopefully I'll be back at it before your JB Weld dries. I'm tempted to suggest something like dental floss with one knot tied around the springs so that it'll pull off easy once they are in, but give you enough to maybe pull it out of the black hole should the worst happen. Might just get in the way though.

#42

Registered User

Thread Starter

Ok, got the magnets in the cap in right order..... never took them out, just put them back in place where they are suppose to be ...you can see the markings where they used to be!!! I went up and bought a general epoxy to glue the magnets back in .... do you think epoxy will do the trick?

As far as the freewheeling stator... I was wrong , I tried it again and I felt it winding the spring inside up...woohoo!!!!

Now the darn brushes.... I ended up putting a paper towel down in the hole to stop from losing them into the abyss....it took me about an hour to get them in with alot of work. When I got them in, I put the stator back and tried turning it.....big mistake...it wound the spring and pushed the stator up and dislodged the brushes again.... another half hour went by and finally back together again.

So I got it left on the truck like that for now until I finish with the cap and magnets. When I get that done Im ready to put back on the truck....I hope the magnets dont pull the stator up on me again..... ill try and keep it down with a screwdriver while I install the cap!!!

So what do you think about epoxy???

Sorry to hear that your under the weather, hope you feel better soon!!! Thanks Beto!!!

As far as the freewheeling stator... I was wrong , I tried it again and I felt it winding the spring inside up...woohoo!!!!

Now the darn brushes.... I ended up putting a paper towel down in the hole to stop from losing them into the abyss....it took me about an hour to get them in with alot of work. When I got them in, I put the stator back and tried turning it.....big mistake...it wound the spring and pushed the stator up and dislodged the brushes again.... another half hour went by and finally back together again.

So I got it left on the truck like that for now until I finish with the cap and magnets. When I get that done Im ready to put back on the truck....I hope the magnets dont pull the stator up on me again..... ill try and keep it down with a screwdriver while I install the cap!!!

So what do you think about epoxy???

Sorry to hear that your under the weather, hope you feel better soon!!! Thanks Beto!!!

#43

What'd you use? 5 minute stuff? As long as everything is clean should be OK. You might want to spray some liquid grease in to the vent hole, now that you see how everything works in there, WD-40 tends to dry things out after a while. How's your top-cap bearing? Looks like everything is going to be OK for you, glad to hear it.

#44

On second thought, if you haven't glued them yet, you might want to get the JB weld. The strongest stuff possible - the factory glue doesn't seem to hold up at all. This problem is very common. Your epoxy should work, but do you really want to go through this again next year? I would mark the magnets with a felt or paint, then scrub everything clean as possible with emery cloth and then brake cleaner or acetone, make sure you get a good bond.

#45

Registered User

Thread Starter

Yeah it says 5 minute stuff but takes 4 hours for complete drying time.....I put alot of wd40 in the vent hole, so much that it started running out when i rotated the actuator. Will put some liquid grease in there anyway..... it will be a slurry of fluids...lol. tThe top cap bearing looks perfect.....well im not getting my hopes up yet, but at least I have a chance of repair here!!! Will let you know how I make out!!!

#46

Registered User

Thread Starter

I havent use the epoxy yet.... I am getting rid of the truck in April to buy a new one, I just need to get through the winter one more time...lol. So what do you think? Should I go buy JB Weld.....what ever you suggest!!

#47

Up to you. If it breaks, you'll know how to fix it again, right? I'm kind of anal about things like that anyways. I went as far as to sandblast the inside and outside of my RR diff lock and repaint everything. For what? probably didn't help it work any better!

#48

Registered User

Thread Starter

Ok, I'm gonna use the epoxy since i have it here...and your right, if it breaks I will know exactly what to do....... I like doing things the right way to, but its an easy fix if it breaks loose in a month or so... its only 2 screws .... that is if the brushes dont pop out again!!! I'll keep ya posted!!! I hope this is an end to this problem!!!! Thanks!!!

#49

Registered User

Thread Starter

Alright........ I just put the truck back on the ground, got everything put back together and its all a waiting game now.....well, I let the epoxy dry for about an hour on those magnets before I put the cap back on, now another 3 hours of drying time and its time to crank her up. A nice feeling to have everything put back together, but nothing worst than having to wait and see if it fixed the problem!!! To be safe, I'm gonna wait till tomorrow morning...just to be sure!!! Fingers crossed!!!

#51

Registered User

Thread Starter

Ok Beto, got up this morning to try the 4x4 for the first time... I jump in the truck, start to drive, push the 4wd button and she went into 4wd just like the day she was new.... so I figured I gotter fixed!!! Not so, the problem came when I went to disengage the 4wd... it wouldnt come out.....strange!!! I dont know if the epoxy let go, but I cant see that happening so fast..... so I drove to work in 4wd!!! When I got work I decided to crawl under the truck and unplug the position sensor.... it worked, it came out of 4x4 but that just disengaged the front actuator.... the transfer case actuator is still engaged of course. Now, Im here at work and trying to decide what to do...remember you told me if I just bypass the position sensor switch and the t-case actuator disengaged, I would get a harsh bang in the truck. I dont want that to happen, so I guess I should plug the position sensor switch back in until I an put a toggle in series... I will be in 4wd driving home again, and I dont like doing that on dry pavement (of course the snow melts now)!!! Argh, what to do.... I'm going to have to take that cap off again and see it things are still in place...but that will have to wait til tonight. In the mean time I'm gonna have to drive in 4wd.... and make the best of it, I just put 2 of my winter tires on the back of the truck (225/75/15) and the front tires are (235/75/15)....so the front it rotating a little faster/slower creating more tension on the system... I dont know if I should leave the cap alone and just use the bypass method or take that chance of removing that cap again and possibly having to fiddle with the brushes again???

#52

The bang will only happen if your A.D.D. system engages while the transfer is in 2WD and you are moving. The following are OK: ADD engage at any speed when transfer in 4WD, ADD disengage at any time when transfer is in 2WD or 4WD, ADD engage in 4WD or 2WD when stopped.

Unplug your position switch - If the actuator happens to behave and back out, you'll have no issues getting home. Just don't try 4WD until you have more info..

Curious what it could be now...

Unplug your position switch - If the actuator happens to behave and back out, you'll have no issues getting home. Just don't try 4WD until you have more info..

Curious what it could be now...

Last edited by Beto; 11-09-2009 at 05:21 AM.

#53

Registered User

Thread Starter

Yeah I'm stumped... as soon as I pushed the button this morning, it went in immediately, no hesitation what so ever!!! The only thing I can think of is the epoxy letting go....do you think? So, what you are saying is that it is safe for me to leave the position sensor unplugged to drive home and should I have the 4wd button pushed in or left out...I'm thinking in, how bout you??

Last edited by kennyyoung; 11-09-2009 at 05:47 AM.

#54

Registered User

Thread Starter

Am I just as well to go ahead and bypass that sensor now that I have the t-case engaged... all that will do is keep the front stubby turning all the time won't it? I'm nervous about picking it apart again and not getting it to work at all.... this way I know I will have 4wd!!! My only conecern with taking the cap off again is the darn brushes...they are misery to get in....and the possibility of losing a spring or breaking one of the little copper wires on the brush itself!!! I know what i'm like..... i'm gonna take the cap off again and create more trouble, I can see it coming.... I got no luck!!!

Last edited by kennyyoung; 11-09-2009 at 05:56 AM.

#55

Page 1091 of your FSM pdf that we downloaded previously. You should be able to find the ground on pin 2 of the transfer 4WD switch (ball bearing switch) and interrupt it with your toggle. That's handy, only one wire to run and no relay - and safe - no chance of bad bangs.

Do you think you'll be able to live with that? never knowing? I see a cap removal in your future! Either way, I'm not going to encourage you one way or the other.

For your trip home, I'd either leave the button pushed in and/or pull the 4WD fuse to make sure the windings in your actuator don't get too hot trying to turn against broken magnets.

Keeping the transfer engaged all the time - always moving, heating up transfer oil = lower fuel economy + increased wear on transfer and u-joints. Some people say that unloaded u-joints spinning around is bad for them, I ran mine for 3 or 4 years like that (the opposite of you though) w/o any issues.

Edit* if you can find the wire color that goes to pin 1 of the 4WD (ball bearing) switch, you can do it right inside the cab near the 4WD ECU, just make sure it's after the splice that goes to the ADD system. ***

Do you think you'll be able to live with that? never knowing? I see a cap removal in your future! Either way, I'm not going to encourage you one way or the other.

For your trip home, I'd either leave the button pushed in and/or pull the 4WD fuse to make sure the windings in your actuator don't get too hot trying to turn against broken magnets.

Keeping the transfer engaged all the time - always moving, heating up transfer oil = lower fuel economy + increased wear on transfer and u-joints. Some people say that unloaded u-joints spinning around is bad for them, I ran mine for 3 or 4 years like that (the opposite of you though) w/o any issues.

Edit* if you can find the wire color that goes to pin 1 of the 4WD (ball bearing) switch, you can do it right inside the cab near the 4WD ECU, just make sure it's after the splice that goes to the ADD system. ***

Last edited by Beto; 11-09-2009 at 06:13 AM.

#56

Registered User

Thread Starter

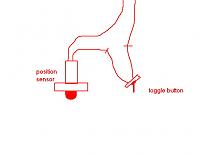

You know me to well... no, I cant live with not knowing....and yes, I will pull the cap off again!!!LOL As far as the toggle switch goes ... im going to do a drawing up and post it to make sure im gonna do it right....back in 5 minutes with a pic!!!

#58

Registered User

Thread Starter

#59

That'll do it. Might be cleaner ways to do it, like right at the ECU, but that's sure to work. Should also open up the possibility of L2 even if your actuator starts working. Maybe not much utility for this in an Auto, but was good in my manual for very slow tricky stuff like hooking up a boat.

#60

Registered User

Thread Starter

I dont know what you mean by a possibility of L2.... I know you mean LOW 2, but how would it do that? I already have Low range on the shifter.... is that what you mean?

Last edited by kennyyoung; 11-09-2009 at 06:41 AM.