Synthetic oil in an 87 22r with 160,000?

#22

Registered User

I ran Royal Purple synthetic in an 86 22re with about 160K on the ticker and never had a leak, engine was in great shape. Tried the same thing on my 89 4runner with 200K++ on it and had an instant leak in the rear main, went back to dino and the leak stopped. It all depends on how the engine was treated before. Synthetic will not ruin the engine.

Heard the same thing about Fram filters plugging up but have no first hand knowledge of that. I currently run the Napa Gold filter on my 89 and have run the same filter on several rigs (86 Toyota, 79 IH Scout II diesel, 76 IH Scout II gasser, 97 F350 diesel, 86 F250 diesel, etc...) and never had an issue.

As far as shocks go you can go to Napa and pick up the factory replacement Monroe Synsatracs (spelling??) for about 30$ a pair and run those. I ran them on my 86 Toy and liked them. Since you're not doing any crazy trails I think those shocks would work for you.

Oh and welcome to the addiction.

Heard the same thing about Fram filters plugging up but have no first hand knowledge of that. I currently run the Napa Gold filter on my 89 and have run the same filter on several rigs (86 Toyota, 79 IH Scout II diesel, 76 IH Scout II gasser, 97 F350 diesel, 86 F250 diesel, etc...) and never had an issue.

As far as shocks go you can go to Napa and pick up the factory replacement Monroe Synsatracs (spelling??) for about 30$ a pair and run those. I ran them on my 86 Toy and liked them. Since you're not doing any crazy trails I think those shocks would work for you.

Oh and welcome to the addiction.

#23

Registered User

https://www.treadwright.com/c-5-235-75r15.aspx

Great tires on a budget. Don't let the retread thing scare you off. I've owned two sets and love them. Wear like iron and grip really well. Since this is your DD and hunting rig these tires could work well for you.

If you're on a budget then keep the stock wheels that are on the rig, no reason to buy another set if yours are in good shape.

#24

Registered User

(Warning: dissertation ahead, lol)

Most "synthetic" oils on the market, like Rotella T6, are group III, which are derived from petroleum, and do not tend to cause leaks. It's the "true synthetic" group IV PAO oils that gave synthetic oil the reputation for causing leaks, because PAOs dry and shrink plastic seals. The original Mobil 1 formulation was PAO and it caused leaks in a lot of older motors (Mobil changed to cheaper group III basestock a decade or so ago). The other type of "true synthetic" is group V ester stocks, like Red Line. Esters have the opposite effect on seals from PAOs - esters cause seals to swell and soften. AMSOIL is primarily PAO, but they blend in sufficient esters to counteract the seal drying effect, so it doesn't cause seals to leak (any more than they already are). However, there is another way that true synthetics may cause leaks: esters are strongly polarized molecules that act just like detergents, and remove sludge quite effectively. Since sludge may be plugging gaps that otherwise would be leaking oil, the true syns may cause leaks in older motors simply due to the sludge removal.

Group IIIs - which include Rotella T6, Pennzoil Platinum, Valvoline Synpower, Castrol Syntec and Mobil 1 - won't shrink seals and don't have a very strong detergent effect, so they probably won't cause leaks any more than conventional petroleum oil. They do offer much of the performance benefits of the "true synthetic" oils, though. That includes an increased viscosity index (doesn't thicken at cold temps or thin at high temps as much as conventional oil) which gives superior cold flow. And because of the naturally higher viscosity index, they contain less viscosity index improvers, plastic polymer molecules added to conventional oil to thicken it as it gets hot. (A 10W-30 is a 10 weight oil with VIIs added, and a 5W-30 is a 5 weight oil with MORE VIIs added.) VIIs are undesirable because they break down over time, causing the oil to thin out at operating temp, below the rating of the oil. So a conventional 10W-30 often will shear to a 10W-20 within 4-5 k miles, while almost all conventional 5W-30 shear to 5W-20 within 2-3 k miles.

Because all synthetics have better viscosity indexes, they need less VIIs, so they don't shear as quickly and can be used for more miles. Most group IIIs are fine for 5 k miles or so, while the true syn groups IV and V oils can last as long as 8-10 k miles.

Since the group IIIs offer some of the benefits of the true syns at much lower cost, I think they're the bargains of the oil market. They're good oils for any motor, even a higher mile one. I used to use Castrol Syntec and had good luck with it, but I switched to Rotella T6 5W-40 last fall and it seems to be doing really well. I plan to keep using it, since I like that it contains sufficient zddp (1200 ppm), the anti-wear additive that has been stripped from modern API rated oils, supposedly because of concern it would damage catalytic converters. I replaced my original cat last year after 21 years of using zddp-containing oils, and the new cat hardly improved my emissions test result at all. So I think the claim that zddp damages cats is a bunch of hogwash.

PAOs such as the ones in AMSOIL are probably the toughest lubricants on the market, and AMSOIL blends in enough esters to protect seals. But many of the AMSOIL products are blended to meet the modern API SM spec which forbids using sufficient levels (1200-1400 ppm) of zddp to provide the best protection to the cam followers in the 22R series motors. (API SM limits zddp to about 800 ppm.) So for 22R series motors I would choose one of the AMSOIL products that have more zinc, which includes their 10W-40 AMO, 10W-30 Z-ROD 10W-30, or Series 3000 5W-30 diesel oil. (Some suggest the Z-Rod products are group III, not group IV PAO.)

http://www.amsoil.com/techservicesbu...t%20tappet.pdf

The problem with group V esters such as the Red Line oils is that esters tend to absorb water, which can limit their longevity. I would consider Red Line for a racing motor, but I'm not sure about using it in our trucks.

For motors with leaking seals, I highly recommend the high mileage Valvoline MaxLife 10W-40. It's a great semi-synthetic (group III) oil with very good used oil analysis reports and excellent longevity and it has extra seal-swelling esters. I switched to it last spring because of a significant front main seal leak and minor rear main seal leak. In two weeks, both leaks stopped. I changed the front main seal when I replaced my timing belt last fall, and I switched to the Rotella T6 since it's a better winter oil (5W instead of 10W). I was a little worried about the rear main seal, and figured I might need to switch back to the MaxLife for the summer months. I was happy to find that by spring the rear seal was still holding tight, so I've continued using the full syn zddp-containing T6. So far (knocking wood!), the rear seal hasn't started leaking again, so I think the T6 must have some esters in it. It's a nice oil, and would probably do well in most 22Rs, REs or 3VZEs that are middle-aged or older. Lower mile motors with tight bearings would probably do better with a 10W-30 or synthetic 5W-30. I wouldn't recommend using a conventional 5W-30 in any motor since it's mostly VIIs and breaks down so quickly.

Most "synthetic" oils on the market, like Rotella T6, are group III, which are derived from petroleum, and do not tend to cause leaks. It's the "true synthetic" group IV PAO oils that gave synthetic oil the reputation for causing leaks, because PAOs dry and shrink plastic seals. The original Mobil 1 formulation was PAO and it caused leaks in a lot of older motors (Mobil changed to cheaper group III basestock a decade or so ago). The other type of "true synthetic" is group V ester stocks, like Red Line. Esters have the opposite effect on seals from PAOs - esters cause seals to swell and soften. AMSOIL is primarily PAO, but they blend in sufficient esters to counteract the seal drying effect, so it doesn't cause seals to leak (any more than they already are). However, there is another way that true synthetics may cause leaks: esters are strongly polarized molecules that act just like detergents, and remove sludge quite effectively. Since sludge may be plugging gaps that otherwise would be leaking oil, the true syns may cause leaks in older motors simply due to the sludge removal.

Group IIIs - which include Rotella T6, Pennzoil Platinum, Valvoline Synpower, Castrol Syntec and Mobil 1 - won't shrink seals and don't have a very strong detergent effect, so they probably won't cause leaks any more than conventional petroleum oil. They do offer much of the performance benefits of the "true synthetic" oils, though. That includes an increased viscosity index (doesn't thicken at cold temps or thin at high temps as much as conventional oil) which gives superior cold flow. And because of the naturally higher viscosity index, they contain less viscosity index improvers, plastic polymer molecules added to conventional oil to thicken it as it gets hot. (A 10W-30 is a 10 weight oil with VIIs added, and a 5W-30 is a 5 weight oil with MORE VIIs added.) VIIs are undesirable because they break down over time, causing the oil to thin out at operating temp, below the rating of the oil. So a conventional 10W-30 often will shear to a 10W-20 within 4-5 k miles, while almost all conventional 5W-30 shear to 5W-20 within 2-3 k miles.

Because all synthetics have better viscosity indexes, they need less VIIs, so they don't shear as quickly and can be used for more miles. Most group IIIs are fine for 5 k miles or so, while the true syn groups IV and V oils can last as long as 8-10 k miles.

Since the group IIIs offer some of the benefits of the true syns at much lower cost, I think they're the bargains of the oil market. They're good oils for any motor, even a higher mile one. I used to use Castrol Syntec and had good luck with it, but I switched to Rotella T6 5W-40 last fall and it seems to be doing really well. I plan to keep using it, since I like that it contains sufficient zddp (1200 ppm), the anti-wear additive that has been stripped from modern API rated oils, supposedly because of concern it would damage catalytic converters. I replaced my original cat last year after 21 years of using zddp-containing oils, and the new cat hardly improved my emissions test result at all. So I think the claim that zddp damages cats is a bunch of hogwash.

PAOs such as the ones in AMSOIL are probably the toughest lubricants on the market, and AMSOIL blends in enough esters to protect seals. But many of the AMSOIL products are blended to meet the modern API SM spec which forbids using sufficient levels (1200-1400 ppm) of zddp to provide the best protection to the cam followers in the 22R series motors. (API SM limits zddp to about 800 ppm.) So for 22R series motors I would choose one of the AMSOIL products that have more zinc, which includes their 10W-40 AMO, 10W-30 Z-ROD 10W-30, or Series 3000 5W-30 diesel oil. (Some suggest the Z-Rod products are group III, not group IV PAO.)

http://www.amsoil.com/techservicesbu...t%20tappet.pdf

The problem with group V esters such as the Red Line oils is that esters tend to absorb water, which can limit their longevity. I would consider Red Line for a racing motor, but I'm not sure about using it in our trucks.

For motors with leaking seals, I highly recommend the high mileage Valvoline MaxLife 10W-40. It's a great semi-synthetic (group III) oil with very good used oil analysis reports and excellent longevity and it has extra seal-swelling esters. I switched to it last spring because of a significant front main seal leak and minor rear main seal leak. In two weeks, both leaks stopped. I changed the front main seal when I replaced my timing belt last fall, and I switched to the Rotella T6 since it's a better winter oil (5W instead of 10W). I was a little worried about the rear main seal, and figured I might need to switch back to the MaxLife for the summer months. I was happy to find that by spring the rear seal was still holding tight, so I've continued using the full syn zddp-containing T6. So far (knocking wood!), the rear seal hasn't started leaking again, so I think the T6 must have some esters in it. It's a nice oil, and would probably do well in most 22Rs, REs or 3VZEs that are middle-aged or older. Lower mile motors with tight bearings would probably do better with a 10W-30 or synthetic 5W-30. I wouldn't recommend using a conventional 5W-30 in any motor since it's mostly VIIs and breaks down so quickly.

Last edited by sb5walker; 09-15-2011 at 05:15 PM.

#26

Registered User

Join Date: Jan 2005

Location: Leadville Colorado

Posts: 1,600

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, this man knows his oil! I'm a big fan of Rotella T6 syn as well, been running it for 30K miles in my 22RE and it does well. I had no leaks or consumption issues before and still don't.

#27

Registered User

Haha, thanks, yeah, I don't know where my apparent fascination with petroleum products came from, but thought I'd share it

I'd feel bad tho if I wrenched this thread back to the original topic when the off topic posts and pics were getting so interesting

I'd feel bad tho if I wrenched this thread back to the original topic when the off topic posts and pics were getting so interesting

#28

Registered User

Just ran across this posting over on the bobistheoilguy forum, and thought it might shed a little light on the T6 formulation:

http://www.bobistheoilguy.com/forums...Number=1367272

Also found some UOAs (used oil analysis reports) for T6 that show it holding up really well under stress for many miles. Here's one for a Subaru 2.5 liter 4 cyl - the smaller, higher rpm motors tend to put a lot of shear stress on oil. This report shows the results after 8 thousand miles of use, remarkable:

(From this thread: http://www.bobistheoilguy.com/forums...91#Post1361791 )

First, the wear metals, aluminum, copper and iron are quite low, especially for that many miles. (Except for the copper, which apparently is a situation specific to that motor). Compare to the previous oil used in the motor (OP said it was Mobil 1 5W-30) shown in the two columns to the right. Those were run for only 2.5 & 3k miles. Normally, wear metals go up proportional to miles, so the 8k on the T6 should show about three times more wear metals, but instead they are lower!

The much better wear protection may be due to more zddp (note the amount of zinc in the T6, 1369 ppm, relative to the M1 5W-30. That's a normal SM rated oil with about 800 ppm zinc). Lower wear with the T6 possibly also due to the higher viscosity.

Second, the viscosity at operating temp (the cSt 100 deg C number) is still a 40 weight (the 40 weight visc goes down to 12.5 cSt). That's really amazing performance, given that the oil ranges from 5W up to 40 - an 8x increase which usually requires mega VIIs, usually meaning quick shearing. So T6 must not have mega VIIs (they would break down a lot after 8k miles), and so the viscosity index of the base oil itself has to be quite high - actually close to PAO performance. Note the M1 viscosity is almost down to 20 weight (9.29 cSt or below) by 3k miles or less. That's typical for supposedly "synthetic" Mobil 1 btw; it shears nearly as badly as mineral oils.

Here's a chart showing the viscosity values for the different SAE Engine Oil weights:

A 30 weight is cSt 9.3 - 12.49 at operating temp (100 deg C)

Third, note the "TBN" number is still high after 8k miles: 5.0. Total Base Number is a measure of the buffering capacity in the oil, needed to neutralize the acids that normally form. When that gets down to 1, the oil is done. Most diesel oils have extra buffering (in the form of calcium and magnesium additives) since diesel engines produce more acids. T6 starts out around 10, so a TBN of 5 at 8k miles is good. Our older motors probably produce more acids than that Mazda, though, so that's another good reason to use diesel oils.

Here are some other UOAs for T6, all of them showing low wear metals (including copper) and excellent viscosity stability. One of them was for an engine that was actually raced, which REALLY shears oils:

http://www.bobistheoilguy.com/forums...Number=2078804

http://www.bobistheoilguy.com/forums...Number=1937230

http://www.bobistheoilguy.com/forums...Number=2128257 (good grief, a turbocharged motor and the oil was used for 10k miles!)

http://www.bobistheoilguy.com/forums...Number=1992028 (this car was raced - note that the viscosity drops to 30 weight because of it, but the wear metals are amazingly still low)

http://www.bobistheoilguy.com/forums...Number=1937984 Here's the full-size UOA from that thread:

http://i784.photobucket.com/albums/y.../UOAs/audi.jpg

Looks like T6 does a very good job protecting motors from wear, and holds its viscosity almost as well as full PAO oils like AMSOIL. And its fairly cheap at wally world.

(No affiliation with Shell btw, lol)

I got this bit of info off of a diesel truck enthusiast web site; supposedly this quote is from a Shell engineer..

"It is true that ROTELLA T Synthetic is Group III (not PAO) based, but you must keep in mind that not all Group III base oils are created equal. ROTELLA T Synthetic is made with Shell's XHVI base oil, which unlike other Group IIIs does not begin as distilled crude oil, hence of all Group III base oils, XHVI is truly the only one that can legitimately be called "synthetic." XHVI is a wax isomerate, meaning that it is made from the slack wax removed from distilled crude in normal solvent dewaxing. This slack wax is catalytically transformed (isomerized) and hydrofinished into a chemically pure base oil which rivals PAO in virtually every category. There are other "synthetic" oils out there based on Group III, but Shell's is unique in that it uses XHVI base oil. Chevron and Petro-Canada produce Group III base oils that come close to XHVI, but even though these oils are all hydroprocessed and utilize the same type of isomerization technology employed in the making of XHVI, they are not the same thing. Only XHVI is made from pure petroleum slack wax and its CAS number is 92026-09-4. The CAS number for the more typical all-hydroprocessed Group III base oils is 64742-54-7. If you want to know what your "synthetic" oil is made from, take a look at the MSDS and look for these numbers. (The CAS number for PAO is 68037-01-4).

In brief, don't be so quick to dismiss Rotella T Synthetic as just another "synthetic pretender." It's made with the same base oil as Shell's Helix Ultra, and everytime you see Ferrari win a Formula 1 race, that's the oil in the engine.""

I'd love to try this stuff in my 330ci and my Mazdaspeed 3 as it is cheaper than most other synthetics and sure sounds good here. I believe in the Used Oil Analysis section someone posted a good UOA in a MS 3 with this oil.

Am I crazy? Do I need a doctor for even thinking of using a diesel oil in some of my cars?

Really just looking for a cheaper way to get really good oil performance. At Walmart this oil is cheap compared to the other synthetics. Are there any negative aspects to my line of thinking?

Putting on flame suit...

"It is true that ROTELLA T Synthetic is Group III (not PAO) based, but you must keep in mind that not all Group III base oils are created equal. ROTELLA T Synthetic is made with Shell's XHVI base oil, which unlike other Group IIIs does not begin as distilled crude oil, hence of all Group III base oils, XHVI is truly the only one that can legitimately be called "synthetic." XHVI is a wax isomerate, meaning that it is made from the slack wax removed from distilled crude in normal solvent dewaxing. This slack wax is catalytically transformed (isomerized) and hydrofinished into a chemically pure base oil which rivals PAO in virtually every category. There are other "synthetic" oils out there based on Group III, but Shell's is unique in that it uses XHVI base oil. Chevron and Petro-Canada produce Group III base oils that come close to XHVI, but even though these oils are all hydroprocessed and utilize the same type of isomerization technology employed in the making of XHVI, they are not the same thing. Only XHVI is made from pure petroleum slack wax and its CAS number is 92026-09-4. The CAS number for the more typical all-hydroprocessed Group III base oils is 64742-54-7. If you want to know what your "synthetic" oil is made from, take a look at the MSDS and look for these numbers. (The CAS number for PAO is 68037-01-4).

In brief, don't be so quick to dismiss Rotella T Synthetic as just another "synthetic pretender." It's made with the same base oil as Shell's Helix Ultra, and everytime you see Ferrari win a Formula 1 race, that's the oil in the engine.""

I'd love to try this stuff in my 330ci and my Mazdaspeed 3 as it is cheaper than most other synthetics and sure sounds good here. I believe in the Used Oil Analysis section someone posted a good UOA in a MS 3 with this oil.

Am I crazy? Do I need a doctor for even thinking of using a diesel oil in some of my cars?

Really just looking for a cheaper way to get really good oil performance. At Walmart this oil is cheap compared to the other synthetics. Are there any negative aspects to my line of thinking?

Putting on flame suit...

Also found some UOAs (used oil analysis reports) for T6 that show it holding up really well under stress for many miles. Here's one for a Subaru 2.5 liter 4 cyl - the smaller, higher rpm motors tend to put a lot of shear stress on oil. This report shows the results after 8 thousand miles of use, remarkable:

(From this thread: http://www.bobistheoilguy.com/forums...91#Post1361791 )

First, the wear metals, aluminum, copper and iron are quite low, especially for that many miles. (Except for the copper, which apparently is a situation specific to that motor). Compare to the previous oil used in the motor (OP said it was Mobil 1 5W-30) shown in the two columns to the right. Those were run for only 2.5 & 3k miles. Normally, wear metals go up proportional to miles, so the 8k on the T6 should show about three times more wear metals, but instead they are lower!

The much better wear protection may be due to more zddp (note the amount of zinc in the T6, 1369 ppm, relative to the M1 5W-30. That's a normal SM rated oil with about 800 ppm zinc). Lower wear with the T6 possibly also due to the higher viscosity.

Second, the viscosity at operating temp (the cSt 100 deg C number) is still a 40 weight (the 40 weight visc goes down to 12.5 cSt). That's really amazing performance, given that the oil ranges from 5W up to 40 - an 8x increase which usually requires mega VIIs, usually meaning quick shearing. So T6 must not have mega VIIs (they would break down a lot after 8k miles), and so the viscosity index of the base oil itself has to be quite high - actually close to PAO performance. Note the M1 viscosity is almost down to 20 weight (9.29 cSt or below) by 3k miles or less. That's typical for supposedly "synthetic" Mobil 1 btw; it shears nearly as badly as mineral oils.

Here's a chart showing the viscosity values for the different SAE Engine Oil weights:

A 30 weight is cSt 9.3 - 12.49 at operating temp (100 deg C)

Third, note the "TBN" number is still high after 8k miles: 5.0. Total Base Number is a measure of the buffering capacity in the oil, needed to neutralize the acids that normally form. When that gets down to 1, the oil is done. Most diesel oils have extra buffering (in the form of calcium and magnesium additives) since diesel engines produce more acids. T6 starts out around 10, so a TBN of 5 at 8k miles is good. Our older motors probably produce more acids than that Mazda, though, so that's another good reason to use diesel oils.

Here are some other UOAs for T6, all of them showing low wear metals (including copper) and excellent viscosity stability. One of them was for an engine that was actually raced, which REALLY shears oils:

http://www.bobistheoilguy.com/forums...Number=2078804

http://www.bobistheoilguy.com/forums...Number=1937230

http://www.bobistheoilguy.com/forums...Number=2128257 (good grief, a turbocharged motor and the oil was used for 10k miles!)

http://www.bobistheoilguy.com/forums...Number=1992028 (this car was raced - note that the viscosity drops to 30 weight because of it, but the wear metals are amazingly still low)

http://www.bobistheoilguy.com/forums...Number=1937984 Here's the full-size UOA from that thread:

http://i784.photobucket.com/albums/y.../UOAs/audi.jpg

Looks like T6 does a very good job protecting motors from wear, and holds its viscosity almost as well as full PAO oils like AMSOIL. And its fairly cheap at wally world.

(No affiliation with Shell btw, lol)

Last edited by sb5walker; 09-09-2011 at 04:48 PM.

#29

Registered User

iTrader: (5)

Mr. Walker, .......how in the heck is it that you know how to post something I will REALLY WANT TO READ, ...right when I have to leave?????? hahahahaha.  ...>Nice<!

...>Nice<!

BTW, you think I'm kidding? I'm heading to Norwalk to bring someone to a wedding in a hall of records typle deal, .....I've printed this out and will be taking it with me! hahaha. Hey, now I know I have "Toyotamaniaticulitus!"

...>Nice<!

...>Nice<! BTW, you think I'm kidding? I'm heading to Norwalk to bring someone to a wedding in a hall of records typle deal, .....I've printed this out and will be taking it with me! hahaha. Hey, now I know I have "Toyotamaniaticulitus!"

#30

Registered User

Hall of Records deal? You mean this? http://www.edgarcayce.org/_AncientMy...ecordsupd.html

Hey if you mean Norwalk CT I was born there. Some years ago...

Hey if you mean Norwalk CT I was born there. Some years ago...

#32

Registered User

Since the right hand number is the "weight" at 100 deg C (near operating temp), and operating temp of a motor remains about the same no matter the season, choose 30 or 40 depending mainly on how many miles/how loose or tight the bearings. Below around 100-120k miles, a somethingW-30 would probably be best. From 100 to 150k, you could get away with either a 30 or 40. Above 150k ish miles, probably most of our motors would be better protected by a 40.

The left-hand W (winter) number is the weight at 0 degrees F. Choose a number low enough that the oil will flow well at the lowest temp it will see. There is absolutely no harm in going low with the W number. Even a 0W-30 will be much MUCH thicker at zero degrees than a 20W-50 is at operating temp. (In fact the 0W-30 would be thicker at 70 deg F than a 50 at operating temp.) All oils thicken dramatically at low temps, even the synthetics. But at least the synthetics will be flowing; something like a mineral 20W-50 would be cold tar at zero degrees. Rule of thumb, I wouldn't use a 20W below 30 deg F, 15W below 20F, a 10W below 0-10 deg F. 5W (if synthetic) probably good down to -10 or -20 F (depending on the oil). For temps lower than that, choose a 0W-30 or 0W-40.

So a 10W-30 would be good for a motor with less than 100k miles and okay for a motor up to 150k miles, at temps above 0-10 deg F. In lower temps with those miles use a synthetic 5W-30 or 0W-30. For best cold weather performance, a syn 5W-30 would flow much better even below 30 deg F than a 10W-30, and it would never be "too thin" relative to the 10W-30, even in the summer; both are 30 weight at operating temp.

The 5W-40 would be best for motors over 120k (ish) miles, at temps down to -20 F (if it's Rotella T6 or Amsoil) or down to -10 F (some other oil). It's fine to run a (synthetic) 5W-40 (or 5W-30) in the summer; both are much thicker at 70 deg F than at operating temp. Non-synthetic 5W- oils rely too much on VIIs for their operating temp viscosity, IMO, and shear too quickly, and are best avoided.

The left-hand W (winter) number is the weight at 0 degrees F. Choose a number low enough that the oil will flow well at the lowest temp it will see. There is absolutely no harm in going low with the W number. Even a 0W-30 will be much MUCH thicker at zero degrees than a 20W-50 is at operating temp. (In fact the 0W-30 would be thicker at 70 deg F than a 50 at operating temp.) All oils thicken dramatically at low temps, even the synthetics. But at least the synthetics will be flowing; something like a mineral 20W-50 would be cold tar at zero degrees. Rule of thumb, I wouldn't use a 20W below 30 deg F, 15W below 20F, a 10W below 0-10 deg F. 5W (if synthetic) probably good down to -10 or -20 F (depending on the oil). For temps lower than that, choose a 0W-30 or 0W-40.

So a 10W-30 would be good for a motor with less than 100k miles and okay for a motor up to 150k miles, at temps above 0-10 deg F. In lower temps with those miles use a synthetic 5W-30 or 0W-30. For best cold weather performance, a syn 5W-30 would flow much better even below 30 deg F than a 10W-30, and it would never be "too thin" relative to the 10W-30, even in the summer; both are 30 weight at operating temp.

The 5W-40 would be best for motors over 120k (ish) miles, at temps down to -20 F (if it's Rotella T6 or Amsoil) or down to -10 F (some other oil). It's fine to run a (synthetic) 5W-40 (or 5W-30) in the summer; both are much thicker at 70 deg F than at operating temp. Non-synthetic 5W- oils rely too much on VIIs for their operating temp viscosity, IMO, and shear too quickly, and are best avoided.

Last edited by sb5walker; 09-09-2011 at 05:46 PM.

#34

Registered User

) The T6 will probably protect your motor well (it's a 5W-40, probably what you meant to type). BTW, the Purolator PureONE PL20195 looks like one of the best filters for our trucks. It filters better, flows better, and is cheaper than that K&N. Advance Auto carries them.

) The T6 will probably protect your motor well (it's a 5W-40, probably what you meant to type). BTW, the Purolator PureONE PL20195 looks like one of the best filters for our trucks. It filters better, flows better, and is cheaper than that K&N. Advance Auto carries them.https://www.yotatech.com/forums/f116...l#post51231877

Good luck with the carb! You might start a thread for that, some of the guys here have a lot of experience with them and might be able to help.

#36

Registered User

#38

Registered User

Viscosity numbers explained

Since this thread has morphed into somewhat of a FAQ on oil, here's an attempted explanation of viscosity. There are so many different measurements and definitions of viscosity, that it's near impossible to figure out the various specs and I've noticed there's a lot of confusion on the subject.

Basically, there are two types of measurements of viscosity. "Dynamic", or "Absolute" viscosity is the internal friction of a fluid. It basically measures the force required to move two materials with the lubricant between them. A higher absolute viscosity (thickness) fluid will require more force to move the two materials a certain distance, whereas if they were lubricated by a lower viscosity fluid, it would take less force to move them. You can see the effect of this when cranking your motor in very cold temps. It turns over much more slowly, and the reason is that the very cold oil inside the bearings has a much higher dynamic viscosity, so it creates a lot more fluid friction, translating to resistance to rotation of the motor. Dynamic viscosity (internal friction) comes into play at operating temp, too. Higher viscosity fluids create more resistance to rotation, and so the motor uses more of its horsepower just to rotate the crank/cams etc. The end result is that high viscosity oils cause somewhat lower gas mileage.

The most common units of measure of dynamic viscosity are either cP (centipoise - a hundredth of a poise) or mPa S (millipascal/second) 1 cP = 1 mPa S. Basically these are measurements of a force needed to overcome the internal friction of the fluid.

The second type of viscosity measure is "Kinematic" viscosity, which is the resistance to flow of a fluid. Basically, the measuring standards consist of a graduated cylinder with a small capillary tube at the bottom, and they measure the time it takes for the fluid to pour through the small tube. A higher kinematic viscosity is a thicker fluid that takes more time to flow, or put another way, in a given time, a smaller quantity of high viscosity fluid will flow, vs a higher quantity of a lower viscosity fluid. Obviously in a motor, you'll have less oil flow (and higher oil pressure) with a higher viscosity oil than with a lower viscosity oil.

The most common units of measure of kinematic viscosity are either cSt (centiStokes) or SUS (Saybolt Universal Seconds). Both measure time for a fluid to flow through a specific set of laboratory apparatus at a given temperature. The SUS measure is growing obsolete and cSt is most commonly used.

Based simply on viscosity, it would seem you would want a low viscosity oil, since it has less internal friction (better gas mileage) and better flow (more cooling of bearings, and they wouldn't get oil-starved). But viscosity isn't the whole picture by a long shot - oil lubricates by creating an oil film that serves as a cushion keeping metal parts from touching each other. Low viscosity oils make thinner oil films, and it's possible for the film to be thinner than the contaminant particle size, so increased wear results. And it's possible for a film to be so thin that actual metal-to-metal contact happens, resulting in extreme wear and bearing/cam damage. Also, low viscosity oils develop less oil pressure, and sufficient oil pressure is needed to make sure oil gets pumped to the furthest journals and is squeezed into all the gaps. So oil viscosity is a compromise.

This article from an independent machinery lubrication consulting firm does a good job explaining the lower vs. higher viscosity trade-offs:

http://www.machinerylubrication.com/Read/518/motor-oils

SAE (Society of Automotive Engineers) oil grades are based mainly on kinematic measures (cSt or SUS). Each grade covers a range of viscosity. Again, the chart:

So for an oil to be graded (right-hand number) as a 40, its kinematic viscosity (cSt) must be between 12.5 and 16.29 (the chart is a little off) when the oil is 100° C (212° F). And a somethingW-30 must have a 100° C cSt between 9.3 and 12.49. The range for a 50 is 16.3 to 21.89 and for a 20 weight, 5.6 - 9.29 cSt.

The SAE grades were developed before the technology existed to make multi-grade oils. All were single grade petroleum oils, which thicken DRAMATICALLY when cold and which thin out A LOT when hot. This was not a big deal in the summer, when you would choose a 30 or 40 weight oil because it provides enough viscosity when the engine was at operating temp. The problem came in the winter, when the paraffins in the 30 or 40 weight petroleum oils would cause the oil to thicken to the point where they were essentially frozen solid - somewhere near the viscosity of cold molasses or tar. So, in the winter, people were forced to use thinner oils like a 10 weight, just so they could start their engines. The problem was that when the engine reached operating temp, the 10 weight oil had much too low viscosity, and could fail to maintain a sufficiently strong/thick oil film, and much more wear resulted.

That unsatisfactory situation is what led to the development of technology to increase the viscosity index of oils - or to reduce the amount that they thicken when cold, and/or thin when hot. Initial improvements came through development of solvent dewaxing around 1930 (which also removed impurities and improved service life), then additives started to come in as WWII put increased demands on oils. Those included buffering compounds, detergents, corrosion inhibitors, preservatives and chemicals to suppress the natural crystallization or freezing of the oil at low temps which further improved the viscosity index and cold weather performance. And in 1950, as mentioned in an earlier post, viscosity index improvers (VIIs) began to be used - very large polymer (plastic) molecules that unwind when hot, increasing the viscosity (actually just counteracting some of the natural decrease when the oils get hot).

And in the '50s came a new refining process called hydrotreating which involved the use of hydrogen, catalysts, heat and pressure to significantly improve the refining process and increase the viscosity index of base oils. The new hydrotreated oils were classified as "Group II" while the traditional solvent-extracted oils were called Group I. In the late '60s, further developments of hydrotreating called hydrocracking, catalytic dewaxing and wax hydroisomerization came along which led to the Group IIIs which had still higher viscosity indexes, beginning to approach the VI of true synthetic PAOs.

In order to describe the new oils with extended viscosity performance over the old single grade group I oils, the SAE developed a multi-grade rating expressed as two numbers: the winter weight (W) and operating temp weight. For example, a 10W-40 means that when at 0° F, the oil has the same viscosity as a single grade SAE 10 weight at that temp, while at 100° C (210° F), the oil has the same viscosity as a single grade SAE 40 weight. So the oil behaves like a 10 when it's cold, and like a 40 when it's hot - best of both worlds.

Unfortunately, that grading system has resulted in a lot of confusion, since it can seem like the oil is thinner at 0° F (10 weight) than it is at 210° F (40 weight). Of course nothing could be further from the truth. That 40 weight at 210° F for example has a viscosity of about 15 cSt, while the 10 weight at 0° F is around 1200 cSt or 80 times thicker than the 40 weight when hot! Still, that's better than the straight 40 weight at 0° F which would have a cSt of over 6000 and essentially wouldn't flow at all, or using a straight 10 weight which at operating temp has a cSt around 4 - not much better than water.

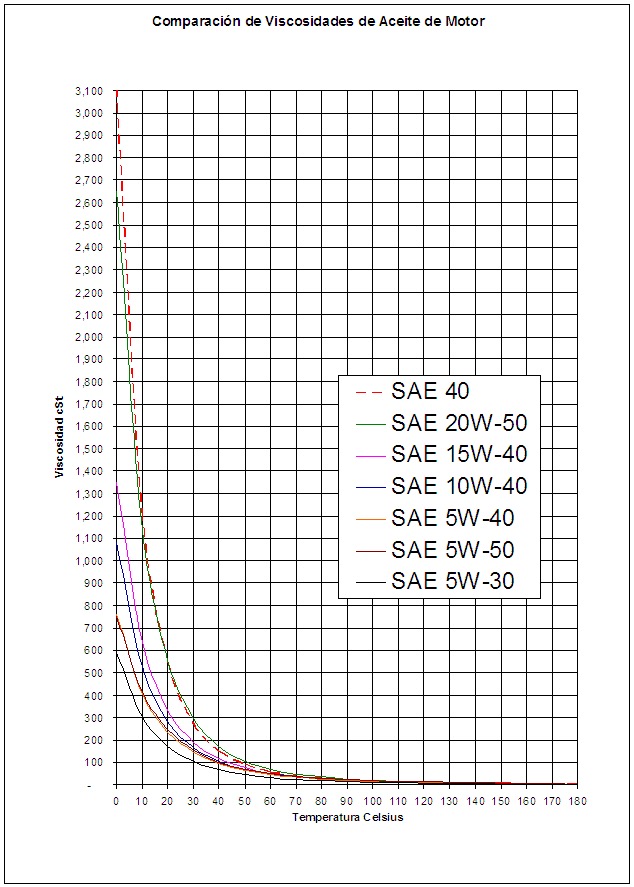

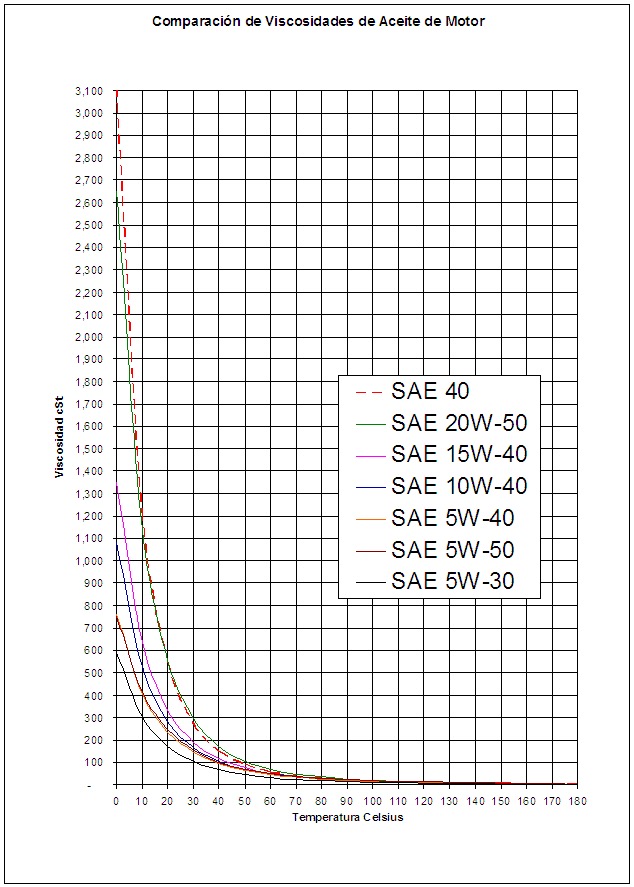

Here's a graph showing typical viscosity curves for different grade oils. It comes from a Bolivian oil company - Widman - and is a rough approximation based on only two points - 40° cSt and 100° cSt and I think the curve is based on typical Group II viscosity performance, so it won't correctly show Group III or IV cold weather performance. The temp range is in Celcius and unfortunately only goes down to 0° C (32° F). Despite those limitations, it does a good job of showing just how much oils thicken at cold temps:

Note that even the 5W-30 is almost 600 cSt at 32° F - more than 30 times thicker than a 20W-50 at operating temp!

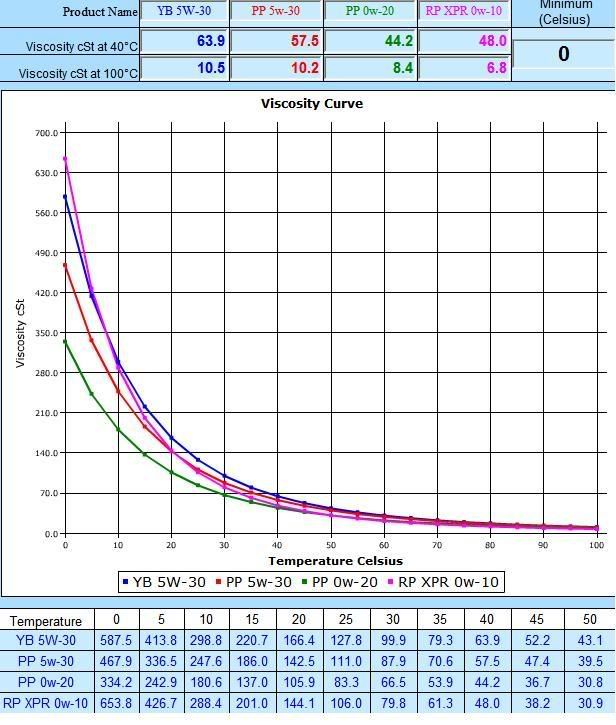

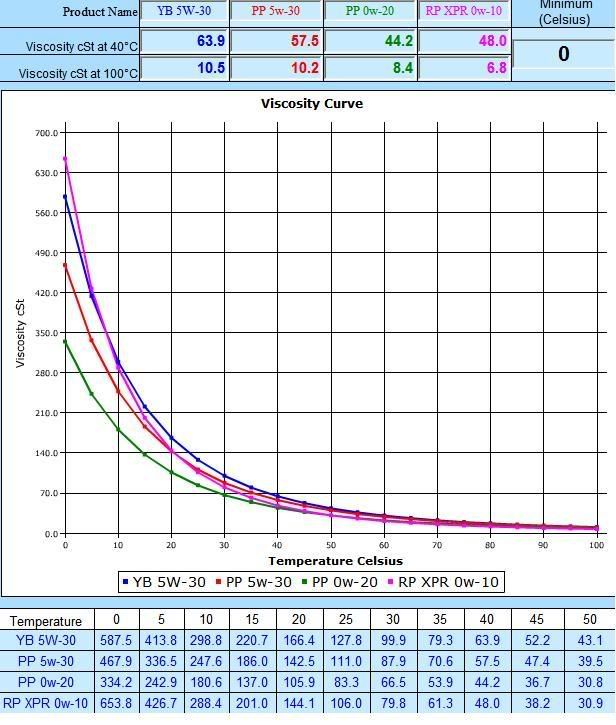

Synthetic oils perform better, but still thicken up amazingly at cold temps. In this graph, PP stands for Pennzoil Platinum, a Group III synthetic. Note that the PP 5W-30 is already up to 468 cSt at 32° F:

These videos give some idea of what goes on inside your motor when at very cold temps:

http://www.youtube.com/watch?v=OWiQyR7PWII

http://www.youtube.com/watch?v=gKtxqf5OFTU

Since the Mobil 1 video does not identify the competitor, the comparison is meaningless, but what is interesting to me is how thick the Mobil 1 5W-30 full synthetic oil is at -40F, which is 14 degrees above its pour point of -54F (-48C). As you can see in the video, it flows like molasses: at that temp you really want to be using a 0W-something synthetic.

Another factor adding to the confusion on cold weather performance is that the industry measures cold performance mainly by dynamic viscosity (cP) while measuring higher temps as kinematic (cSt) and - of course - since they measure different characteristics (friction vs flow), they cannot be converted.

Certainly the moral of the cold weather viscosity story is that you can't go too low with the W number, since even a 0W will be much thicker at cold temps than any oil at operating temp. But if you are using a conventional mineral oil, there is a possible downside to choosing a too-wide viscosity range, since as mentioned, mineral oils achieve the range by the addition of VIIs. Those molecules have some disadvantages. As mentioned upthread, the VIIs are more delicate than the base oils and they break down (shear) from heat and mechanical stress, which causes the operating temp viscosity to drop down a lot over time.

There's another disadvantage to VIIs, and that is something called "temporary polymer shear". Basically when under mechanical stress as in bearings, VII molecules tend to line up and cause the oil to temporarily lose viscosity. So while the oil might be a 5W-30 when it's flowing around the crankcase, when inside the bearing under pressure it might be acting like a 5W-20. Temporary (and permanent) shear happens more with higher amounts of VIIs. In other words, an oil film produced by a mineral 5W-30 is less strong at operating temp than a 10W-30, because the 10W-30 has a thicker base oil and less temp-shearing VIIs.

To get an idea of how much VIIs are in a mineral oil, look at the difference between the two numbers. For a 10W-30, enough VIIs must be added to increase the base 10 weight oil three times (3x). A 10W-40 needs more VIIs to achieve a 4x increase, while the 5W-30 needs 6x worth of VIIs. The UOA reports bear out the fact that the petroleum 5W-30s have the biggest shearing problem of all the mineral multi-grades.

So that's another advantage to the synthetics; because they have naturally higher viscosity indexes, they don't have as much VIIs, suffer from less temporary shear, and have stronger oil films. PAOs like Amsoil have very little or even no VIIs, and suffer little shear. Rotella T6 is a Group III+ and has maybe just a little more VIIs but still performs almost to the PAO level. Normal Group IIIs like Pennzoil Platinum, Valvoline Synpower or Castrol Syntec have a lower natural viscosity index than PAOs and require more VIIs (but not as much as mineral oils). Mobil 1 seems to have more shear trouble than the other Group IIIs and is close to the mineral oils in shear performance. Maybe it should be classified as a Group II+, since both Group IIs (conventional mineral oils) and Group IIIs are refined in the same manner (hydrocracked) but the Group IIIs are refined a little further.

Here are more in-depth explanations of viscosity if you really want to geek out:

http://www.windyridgefarm.us/SaeOil.pdf

http://www.synlube.com/viscosit.htm

http://physics.info/viscosity/

http://www.upmpg.com/tech_articles/motoroil_viscosity/

http://en.wikipedia.org/wiki/Viscosity

http://www.engineeringtoolbox.com/ki...ity-d_397.html

http://www.engineeringtoolbox.com/dy...ity-d_412.html

Basic oil info:

http://en.wikipedia.org/wiki/Motor_oil

http://www.zddplus.com/TechBrief10%2...e%20Stocks.pdf

http://www.widman.biz/uploads/Corvair_oil.pdf

http://www.supramania.com/forums/sho...and-Synthetics

http://www.chevron.com/products/site...eoils/faq.aspx

http://forums.tdiclub.com/showthread.php?t=20080

Here are some other great articles from Noria Corp's Machinery Lubrication journal:

http://www.machinerylubrication.com/...e-oil-industry

http://www.machinerylubrication.com/...oil-technology

http://www.machinerylubrication.com/...ase-oil-trends

http://www.machinerylubrication.com/...nt-formulation

http://www.machinerylubrication.com/Read/618/new-lubes

http://www.machinerylubrication.com/.../synthetic-oil

http://www.machinerylubrication.com/...ased-additives

http://www.machinerylubrication.com/...4/oil-goes-bad

http://www.machinerylubrication.com/.../oil-breakdown

http://www.machinerylubrication.com/...des-lubricated

http://www.machinerylubrication.com/...scosity-limits

http://www.machinerylubrication.com/.../low-viscosity

http://www.machinerylubrication.com/...ng-lubrication

Some articles on the zddp issue:

http://www.foreignpartspositively.com/Article1.htm

http://www.foreignpartspositively.com/Article2.htm

http://www.foreignpartspositively.com/Article3.htm

http://www.classiccarmotoroil.com/ar...html#article-6

http://www.oldcarsweekly.com/restora...l_and_old_cars

http://www.macysgarage.com/myweb6/ZDDP.htm

Shangri-La for oil geeks:

http://www.bobistheoilguy.com/

Basically, there are two types of measurements of viscosity. "Dynamic", or "Absolute" viscosity is the internal friction of a fluid. It basically measures the force required to move two materials with the lubricant between them. A higher absolute viscosity (thickness) fluid will require more force to move the two materials a certain distance, whereas if they were lubricated by a lower viscosity fluid, it would take less force to move them. You can see the effect of this when cranking your motor in very cold temps. It turns over much more slowly, and the reason is that the very cold oil inside the bearings has a much higher dynamic viscosity, so it creates a lot more fluid friction, translating to resistance to rotation of the motor. Dynamic viscosity (internal friction) comes into play at operating temp, too. Higher viscosity fluids create more resistance to rotation, and so the motor uses more of its horsepower just to rotate the crank/cams etc. The end result is that high viscosity oils cause somewhat lower gas mileage.

The most common units of measure of dynamic viscosity are either cP (centipoise - a hundredth of a poise) or mPa S (millipascal/second) 1 cP = 1 mPa S. Basically these are measurements of a force needed to overcome the internal friction of the fluid.

The second type of viscosity measure is "Kinematic" viscosity, which is the resistance to flow of a fluid. Basically, the measuring standards consist of a graduated cylinder with a small capillary tube at the bottom, and they measure the time it takes for the fluid to pour through the small tube. A higher kinematic viscosity is a thicker fluid that takes more time to flow, or put another way, in a given time, a smaller quantity of high viscosity fluid will flow, vs a higher quantity of a lower viscosity fluid. Obviously in a motor, you'll have less oil flow (and higher oil pressure) with a higher viscosity oil than with a lower viscosity oil.

The most common units of measure of kinematic viscosity are either cSt (centiStokes) or SUS (Saybolt Universal Seconds). Both measure time for a fluid to flow through a specific set of laboratory apparatus at a given temperature. The SUS measure is growing obsolete and cSt is most commonly used.

Based simply on viscosity, it would seem you would want a low viscosity oil, since it has less internal friction (better gas mileage) and better flow (more cooling of bearings, and they wouldn't get oil-starved). But viscosity isn't the whole picture by a long shot - oil lubricates by creating an oil film that serves as a cushion keeping metal parts from touching each other. Low viscosity oils make thinner oil films, and it's possible for the film to be thinner than the contaminant particle size, so increased wear results. And it's possible for a film to be so thin that actual metal-to-metal contact happens, resulting in extreme wear and bearing/cam damage. Also, low viscosity oils develop less oil pressure, and sufficient oil pressure is needed to make sure oil gets pumped to the furthest journals and is squeezed into all the gaps. So oil viscosity is a compromise.

This article from an independent machinery lubrication consulting firm does a good job explaining the lower vs. higher viscosity trade-offs:

http://www.machinerylubrication.com/Read/518/motor-oils

SAE (Society of Automotive Engineers) oil grades are based mainly on kinematic measures (cSt or SUS). Each grade covers a range of viscosity. Again, the chart:

So for an oil to be graded (right-hand number) as a 40, its kinematic viscosity (cSt) must be between 12.5 and 16.29 (the chart is a little off) when the oil is 100° C (212° F). And a somethingW-30 must have a 100° C cSt between 9.3 and 12.49. The range for a 50 is 16.3 to 21.89 and for a 20 weight, 5.6 - 9.29 cSt.

The SAE grades were developed before the technology existed to make multi-grade oils. All were single grade petroleum oils, which thicken DRAMATICALLY when cold and which thin out A LOT when hot. This was not a big deal in the summer, when you would choose a 30 or 40 weight oil because it provides enough viscosity when the engine was at operating temp. The problem came in the winter, when the paraffins in the 30 or 40 weight petroleum oils would cause the oil to thicken to the point where they were essentially frozen solid - somewhere near the viscosity of cold molasses or tar. So, in the winter, people were forced to use thinner oils like a 10 weight, just so they could start their engines. The problem was that when the engine reached operating temp, the 10 weight oil had much too low viscosity, and could fail to maintain a sufficiently strong/thick oil film, and much more wear resulted.

That unsatisfactory situation is what led to the development of technology to increase the viscosity index of oils - or to reduce the amount that they thicken when cold, and/or thin when hot. Initial improvements came through development of solvent dewaxing around 1930 (which also removed impurities and improved service life), then additives started to come in as WWII put increased demands on oils. Those included buffering compounds, detergents, corrosion inhibitors, preservatives and chemicals to suppress the natural crystallization or freezing of the oil at low temps which further improved the viscosity index and cold weather performance. And in 1950, as mentioned in an earlier post, viscosity index improvers (VIIs) began to be used - very large polymer (plastic) molecules that unwind when hot, increasing the viscosity (actually just counteracting some of the natural decrease when the oils get hot).

And in the '50s came a new refining process called hydrotreating which involved the use of hydrogen, catalysts, heat and pressure to significantly improve the refining process and increase the viscosity index of base oils. The new hydrotreated oils were classified as "Group II" while the traditional solvent-extracted oils were called Group I. In the late '60s, further developments of hydrotreating called hydrocracking, catalytic dewaxing and wax hydroisomerization came along which led to the Group IIIs which had still higher viscosity indexes, beginning to approach the VI of true synthetic PAOs.

In order to describe the new oils with extended viscosity performance over the old single grade group I oils, the SAE developed a multi-grade rating expressed as two numbers: the winter weight (W) and operating temp weight. For example, a 10W-40 means that when at 0° F, the oil has the same viscosity as a single grade SAE 10 weight at that temp, while at 100° C (210° F), the oil has the same viscosity as a single grade SAE 40 weight. So the oil behaves like a 10 when it's cold, and like a 40 when it's hot - best of both worlds.

Unfortunately, that grading system has resulted in a lot of confusion, since it can seem like the oil is thinner at 0° F (10 weight) than it is at 210° F (40 weight). Of course nothing could be further from the truth. That 40 weight at 210° F for example has a viscosity of about 15 cSt, while the 10 weight at 0° F is around 1200 cSt or 80 times thicker than the 40 weight when hot! Still, that's better than the straight 40 weight at 0° F which would have a cSt of over 6000 and essentially wouldn't flow at all, or using a straight 10 weight which at operating temp has a cSt around 4 - not much better than water.

Here's a graph showing typical viscosity curves for different grade oils. It comes from a Bolivian oil company - Widman - and is a rough approximation based on only two points - 40° cSt and 100° cSt and I think the curve is based on typical Group II viscosity performance, so it won't correctly show Group III or IV cold weather performance. The temp range is in Celcius and unfortunately only goes down to 0° C (32° F). Despite those limitations, it does a good job of showing just how much oils thicken at cold temps:

Note that even the 5W-30 is almost 600 cSt at 32° F - more than 30 times thicker than a 20W-50 at operating temp!

Synthetic oils perform better, but still thicken up amazingly at cold temps. In this graph, PP stands for Pennzoil Platinum, a Group III synthetic. Note that the PP 5W-30 is already up to 468 cSt at 32° F:

These videos give some idea of what goes on inside your motor when at very cold temps:

http://www.youtube.com/watch?v=OWiQyR7PWII

http://www.youtube.com/watch?v=gKtxqf5OFTU

Since the Mobil 1 video does not identify the competitor, the comparison is meaningless, but what is interesting to me is how thick the Mobil 1 5W-30 full synthetic oil is at -40F, which is 14 degrees above its pour point of -54F (-48C). As you can see in the video, it flows like molasses: at that temp you really want to be using a 0W-something synthetic.

Another factor adding to the confusion on cold weather performance is that the industry measures cold performance mainly by dynamic viscosity (cP) while measuring higher temps as kinematic (cSt) and - of course - since they measure different characteristics (friction vs flow), they cannot be converted.

Certainly the moral of the cold weather viscosity story is that you can't go too low with the W number, since even a 0W will be much thicker at cold temps than any oil at operating temp. But if you are using a conventional mineral oil, there is a possible downside to choosing a too-wide viscosity range, since as mentioned, mineral oils achieve the range by the addition of VIIs. Those molecules have some disadvantages. As mentioned upthread, the VIIs are more delicate than the base oils and they break down (shear) from heat and mechanical stress, which causes the operating temp viscosity to drop down a lot over time.

There's another disadvantage to VIIs, and that is something called "temporary polymer shear". Basically when under mechanical stress as in bearings, VII molecules tend to line up and cause the oil to temporarily lose viscosity. So while the oil might be a 5W-30 when it's flowing around the crankcase, when inside the bearing under pressure it might be acting like a 5W-20. Temporary (and permanent) shear happens more with higher amounts of VIIs. In other words, an oil film produced by a mineral 5W-30 is less strong at operating temp than a 10W-30, because the 10W-30 has a thicker base oil and less temp-shearing VIIs.

To get an idea of how much VIIs are in a mineral oil, look at the difference between the two numbers. For a 10W-30, enough VIIs must be added to increase the base 10 weight oil three times (3x). A 10W-40 needs more VIIs to achieve a 4x increase, while the 5W-30 needs 6x worth of VIIs. The UOA reports bear out the fact that the petroleum 5W-30s have the biggest shearing problem of all the mineral multi-grades.

So that's another advantage to the synthetics; because they have naturally higher viscosity indexes, they don't have as much VIIs, suffer from less temporary shear, and have stronger oil films. PAOs like Amsoil have very little or even no VIIs, and suffer little shear. Rotella T6 is a Group III+ and has maybe just a little more VIIs but still performs almost to the PAO level. Normal Group IIIs like Pennzoil Platinum, Valvoline Synpower or Castrol Syntec have a lower natural viscosity index than PAOs and require more VIIs (but not as much as mineral oils). Mobil 1 seems to have more shear trouble than the other Group IIIs and is close to the mineral oils in shear performance. Maybe it should be classified as a Group II+, since both Group IIs (conventional mineral oils) and Group IIIs are refined in the same manner (hydrocracked) but the Group IIIs are refined a little further.

Here are more in-depth explanations of viscosity if you really want to geek out:

http://www.windyridgefarm.us/SaeOil.pdf

http://www.synlube.com/viscosit.htm

http://physics.info/viscosity/

http://www.upmpg.com/tech_articles/motoroil_viscosity/

http://en.wikipedia.org/wiki/Viscosity

http://www.engineeringtoolbox.com/ki...ity-d_397.html

http://www.engineeringtoolbox.com/dy...ity-d_412.html

Basic oil info:

http://en.wikipedia.org/wiki/Motor_oil

http://www.zddplus.com/TechBrief10%2...e%20Stocks.pdf

http://www.widman.biz/uploads/Corvair_oil.pdf

http://www.supramania.com/forums/sho...and-Synthetics

http://www.chevron.com/products/site...eoils/faq.aspx

http://forums.tdiclub.com/showthread.php?t=20080

Here are some other great articles from Noria Corp's Machinery Lubrication journal:

http://www.machinerylubrication.com/...e-oil-industry

http://www.machinerylubrication.com/...oil-technology

http://www.machinerylubrication.com/...ase-oil-trends

http://www.machinerylubrication.com/...nt-formulation

http://www.machinerylubrication.com/Read/618/new-lubes

http://www.machinerylubrication.com/.../synthetic-oil

http://www.machinerylubrication.com/...ased-additives

http://www.machinerylubrication.com/...4/oil-goes-bad

http://www.machinerylubrication.com/.../oil-breakdown

http://www.machinerylubrication.com/...des-lubricated

http://www.machinerylubrication.com/...scosity-limits

http://www.machinerylubrication.com/.../low-viscosity

http://www.machinerylubrication.com/...ng-lubrication

Some articles on the zddp issue:

http://www.foreignpartspositively.com/Article1.htm

http://www.foreignpartspositively.com/Article2.htm

http://www.foreignpartspositively.com/Article3.htm

http://www.classiccarmotoroil.com/ar...html#article-6

http://www.oldcarsweekly.com/restora...l_and_old_cars

http://www.macysgarage.com/myweb6/ZDDP.htm

Shangri-La for oil geeks:

http://www.bobistheoilguy.com/

Last edited by sb5walker; 10-27-2011 at 11:45 PM.

#40

Registered User

iTrader: (3)

Join Date: Apr 2007

Location: Cheshire county, NH

Posts: 509

Likes: 0

Received 0 Likes

on

0 Posts

There's another disadvantage to VIIs, and that is something called "temporary polymer shear". Basically when under mechanical stress as in bearings, VII molecules tend to line up and cause the oil to temporarily lose viscosity. So while the oil might be a 5W-30 when it's flowing around the crankcase, when inside the bearing under pressure it might be acting like a 5W-20. Temporary shear happens more with higher amounts of VIIs. In other words, an oil film produced by a mineral 5W-30 is less strong at operating temp than a 10W-30, because the 10W-30 has a thicker base oil and less temp-shearing VIIs.

To get an idea of how much VIIs are in a mineral oil, look at the difference between the two numbers. For a 10W-30, enough VIIs must be added to increase the base 10 weight oil three times (3x). A 10W-40 needs more VIIs to achieve a 4x increase, while the 5W-30 needs 6x worth of VIIs. The UOA reports bear out the fact that the petroleum 5W-30s have the biggest shearing problem of all the mineral multi-grades.

Thanks for explaining that in clear terms, unless I misunderstood, in which case I'm an idiot.