77 20R won't stay running

#1

77 20R won't stay running

Hey guys, new to the thread world but im gonna give it a try. I have a 77 pickup with a 20R motor. Just the other day i got off of work and drove home. Nothing out of the ordinary, but when i went to leave the next morning it wouldnt stay running. It will start for as long as you have the key cranking the engine. As soon as you let go the motor dies immediately. So i have fuel for the cranking phase and all the others while cranking. I dont know if maybe when i let off the fuel pump shuts off because of some wiring or something. I have checked spark, fuel and air and i have all these things. I am really confused and any help would be Great! Thanks and if you need more info let me know.

#3

Registered User

Compression? Have you checked the oil and antifreeze to see if everything is good? Didn't overheat, did it?

I'm guessing you've checked your vacuum lines to make sure they're all hooked up?

Have you even cleaned the egr valve? You could try disconnecting it and plugging it off and seeing if it starts.

I'm guessing you've checked your vacuum lines to make sure they're all hooked up?

Have you even cleaned the egr valve? You could try disconnecting it and plugging it off and seeing if it starts.

#4

I did check for that. Oil is fine and coolant was good. All the vacuum lines were connected that i could see. Ill have to grab a compresson tester from work but the thing is that when i have the key cranking the motor and hold it i can rev it and it runs fine. Its almost like the fuel pump or some kind of fuel source is running while its cranking. AS SOON as i release the key it dies. I have never seen this issue before.

I know im killing the starter doing this but its just weird and im stumped

I know im killing the starter doing this but its just weird and im stumped

Trending Topics

#8

I did, and I emptied it and it was full after a couple more attempts. But it may be filling from the inlet and not letting any out the outlet. I don't know much about carbs. They don't teach about that in school anymore haha

#9

Registered User

Your fuel pump is quite possibly not mechanical, as most of the late 70's 20R had electronic fuel pumps.

So it's possible that something is only happening when the key is in the start position. Quite possibly electrical. The fuel pump may only be getting a signal when they key is all the way to on/start, or the ignitor or coil is only getting a signal then.

This is definitely beyond the simple stuff I know how to check; just throwing ideas out in case you hadn't thought of them yet.

So it's possible that something is only happening when the key is in the start position. Quite possibly electrical. The fuel pump may only be getting a signal when they key is all the way to on/start, or the ignitor or coil is only getting a signal then.

This is definitely beyond the simple stuff I know how to check; just throwing ideas out in case you hadn't thought of them yet.

#11

Registered User

My 78 has an electric pump, as well as every other 20R, pre-81 or 82, that I've seen. But you never know!

The main difference actually seems to be whether the pump is in the tank, or bolted to the frame just forward of the tank, which is where I think mine is, thankfully.

The main difference actually seems to be whether the pump is in the tank, or bolted to the frame just forward of the tank, which is where I think mine is, thankfully.

#14

Registered User

With a 77? All sorts of things

There could be any number of corroded connections, or cracked something-or-others. Best bet is to check connections from the steering column down- fuses, connections, grounds, wires/insulation.

There are probably things that could be going wrong with the ignitor, coil or distributer. Even though you're getting spark, it might not be functioning properly.

Sorry we can't be more help!

There could be any number of corroded connections, or cracked something-or-others. Best bet is to check connections from the steering column down- fuses, connections, grounds, wires/insulation.

There are probably things that could be going wrong with the ignitor, coil or distributer. Even though you're getting spark, it might not be functioning properly.

Sorry we can't be more help!

#17

#18

Registered User

I have a '78 that I have been "through the mill" with & I've fixed & redone every system, including ignition & fuel. My research (and it's been TONS) tells me that the '77 & '78 are identical in systems and components.

I think you can forget the coil for now. If it starts while cranking the coil is working. Also means your Ignitor (Ignition Control Module) and Distributor Pickup Coil are working. You shouldn't have a ballast resistor on the coil, those were only used with the earlier "points" distributors. If you want to test the coil with an Ohm Meter anyway, the specs are:

Primary Resistance: 1.3 to 1.7 Ohms

Secondary Resistance: 6500 to 10500 Ohms

Make sure you remove/disconnect all 3 leads to the coil before you test it. If you don't have a "self-zeroing" Ohm Meter, connect the leads together on the 200 Ohms scale to see what the resistance is in the test leads, & subtract this amount from the reading for the Primary Resistance. The extra resistance in the leads doesn't matter that much on the Secondary Resistance reading.

Fuel Pump test - The '77 does have an electric fuel pump in the tank. Have you tested it for fuel flow? I mean a visual verification of fuel flow under certain conditions. I would disconnect the fuel feed line to the carb & put the end in a container to catch any gas, then try to start the engine. There should be enough gas left in the carb to do this. If you get flow while cranking & then flow stops when it starts (key released to "RUN" position) see #2 below. If engine starts & you still get THE SAME* fuel flow when key is released to the "RUN" position, see #1 below. Also remember that your truck is 42 years old & probably needs some attention to the things I am going to outline below. My '78 sure did. BTW, fuel flow on these pumps is about 1 quart (32 ounces) every 15 seconds, or approx. 1 gallon per minute, so make sure your catch container is big enough.

I think you have one of 2 different possible problems:

#1 - FUEL/VACUUM ISSUES - Bad Fuel Filter. Idle Passage(s) partially or completely blocked, Throttle Shaft Bushings worn causing a vacuum leak, small crack(s) in rubber fuel line(s), Loose Fuel Line Clamp(s). You didn't say how old your carb was, when it was rebuilt last, whether you've recently cleaned it or not, how old the fuel filter is, what condition the rubber line are in, whether or not you check clamp tightness, & more. You have to go over all the small stuff BEFORE you try diagnosing or replacing parts.

Loose hose clamps can cause the fuel system to suck in air. Same with small cracks in the rubber lines. You said you "emptied out the fuel filter" & it refilled after a few attempts at cranking, but that doesn't mean that the filter media inside is good. Over time the filter can get partially blocked up causing a restriction. Replace the fuel filter, they are cheap, it's easy to do & will give you one less suspect.

Worn Throttle Shaft Bushings can cause large vacuum leaks in the carb. If you recently EXTERNALLY cleaned the carb this could have removed dirt or grime that was acting like a vacuum seal on the worn shaft bushings. The engine will start cold because the choke is making the mixture rich, or will start hot giving it a little extra gas with the pedal. But once started the vacuum leak leans it out too much & it dies. Check for looseness or "wobble" on the shaft; there should be none if it's good. This is the larger shaft at the base of the carb.

Blocked Idle Passage(s) - I had this problem, and with a freshly pro rebuilt carb too. Turns out the Ethanol blend fuel of today was eating away the insides of my old rubber fuel lines. Tiny particles of rubber clogged up my idle passages in the carb, so the engine would start but not keep running. Another good reason to check & perhaps replace your old fuel lines with Ethanol resistant lines. I fixed the problem by removing the fuel bowl drain bolts, idle cutoff solenoid & mixture screw, so I could get access to the idle passages. Used carb cleaner to spray out the fuel bowl, shoot cleaner through both jets, into the port for the solenoid & the mixture screw hole. The blew it all out with some compressed air then put everything back. it worked. Just had to check how many turns out the mixture screw was before completely removing it, so I could put it back at the right "setting". I also replaced every rubber fuel line on the truck with new, ethanol resistant fuel line, as well as all new clamps

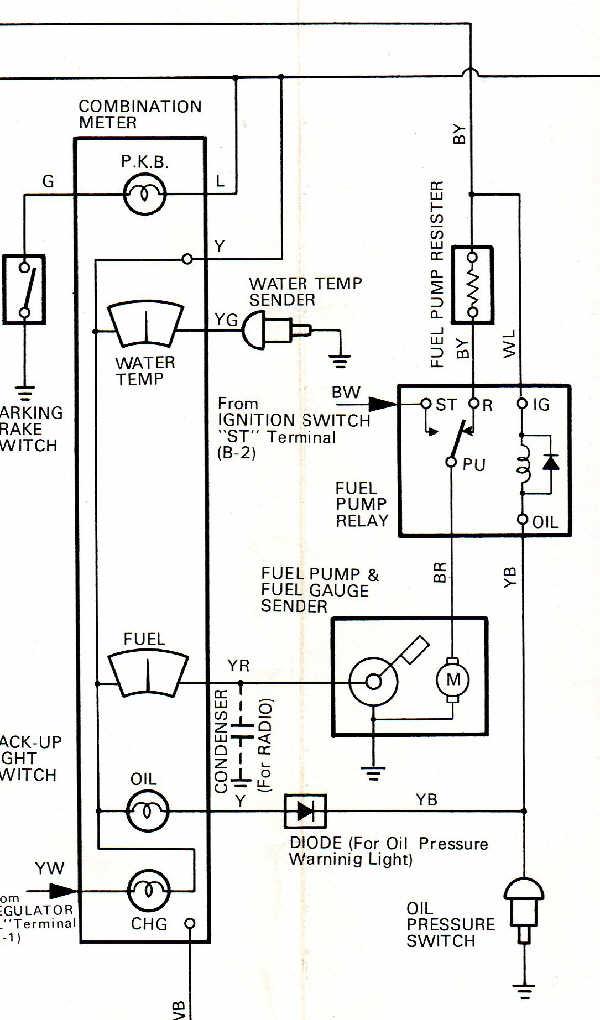

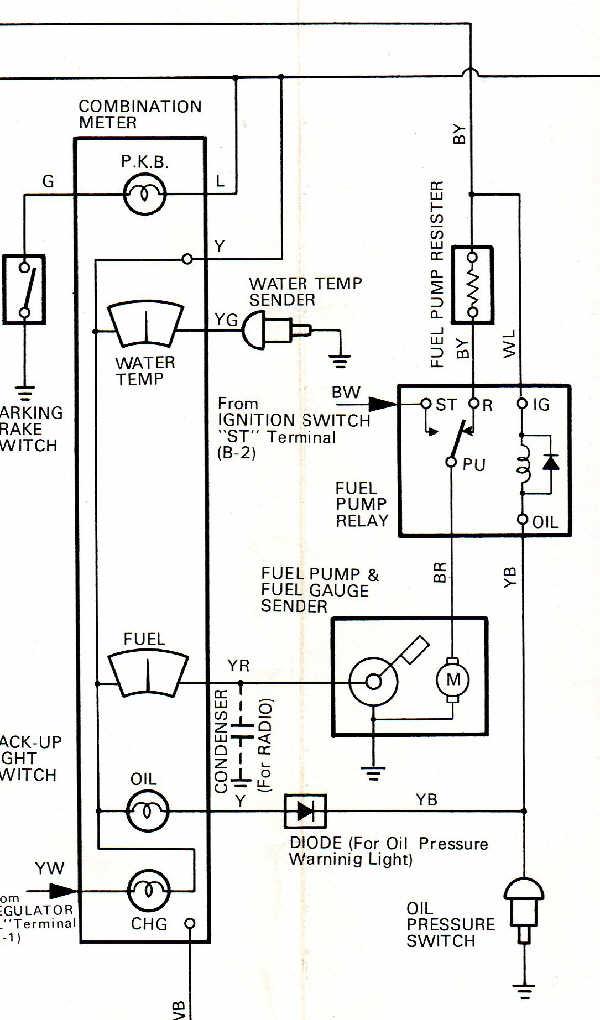

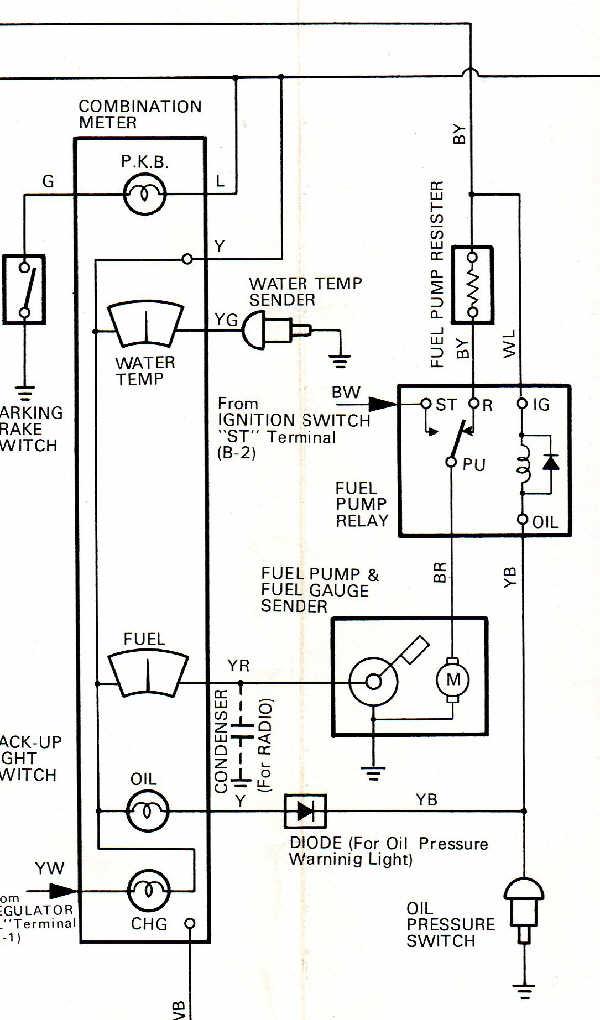

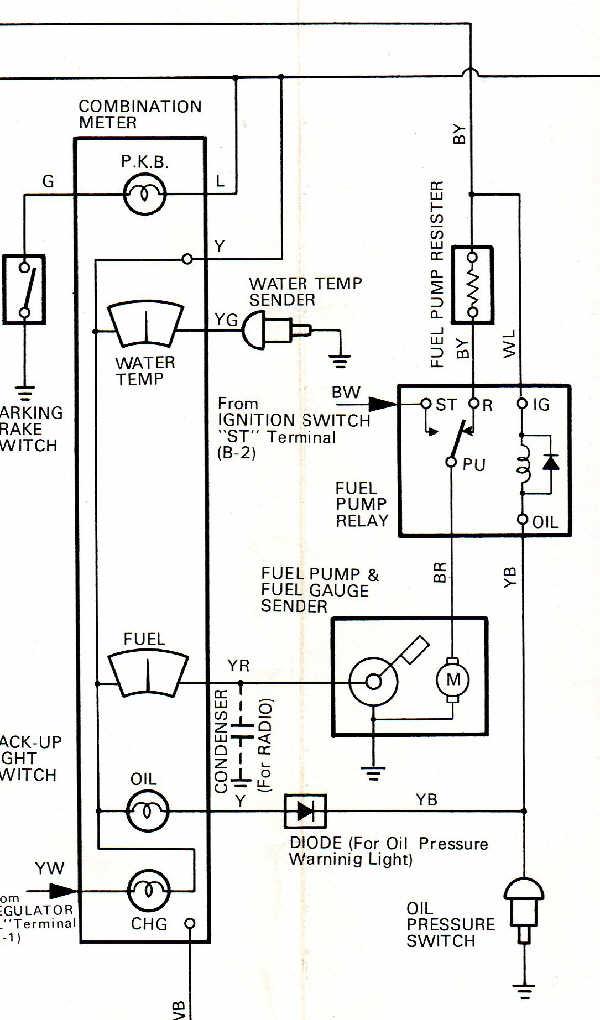

#2 - Issue with the Electrical Circuit for the Fuel Pump. If you get no flow or noticeably reduced flow of fuel when the key is released to the "RUN" position, I would suspect that your Fuel Pump Resistor is the cause. Here is a diagram of the electrical system for the fuel pump:

I will explain the circuit. In looking at the diagram, you'll notice that the fuel pump circuit gets full battery power from the "START" side of the ignition through the Fuel Pump Relay. The relay is energized & switches the "pole" inside the relay to the START side whenever you have low or no oil pressure, thanks to the Oil Pressure Switch. The switch is "closed" at low or no oil pressure & allows voltage to flow to the coil in the relay, and sends voltage to your "OIL" warning light on the dashboard. Once enough oil pressure is built up, the pressure "opens" the switch, turns off the "OIL" light & allows the pole to flop back to the "RUN" side. This brings the resistor into play. The resistor drops the battery voltage to the fuel pump down to about 9.5 volts. This extends the life of the fuel pump & makes it run quieter. The pump is designed to run at this voltage & provide the correct fuel pressure & volume for running conditions.

Over time, the fuel pump resistor, due to exposure to engine heat & who knows how many cycles, will begin to fatigue & change in resistance to a higher level & this only gets worse as it heats up. The higher resistance drops the voltage to a point where there may not be enough voltage to the pump for it to pump properly. My old resistor when hot read more than double it's spec, & my calculations showed the pump was only getting something like 3 volts instead of the usual 9.5 volts(!). This results in little or no fuel flow when the key was in the "RUN" position, & why the engine would not keep running after starting.

First, make sure your fuel pump resistor is still connected & that the contacts in the plug & socket are clean. It is located in top of the passenger side fender well & looks like this:

You can test it with an Ohm Meter like the coil. The spec on it is:

Ceramic Power Resistor, 1.4 Ohms, 10 Watts, 10% Tolerance

Cold, it might read within spec, so it's a good idea to get a hair dryer or heat gun & heat it up some while watching the ohm meter. If it's good, you shouldn't see anything beyond 1.6 Ohms, even when hot (200 F maximum). When I tested mine with a hair dryer it eventually topped out at 2.9 Ohms, more than double the original spec.

You can also test it by bypassing the resistor. Disconnect the green plug & put a jumper wire in the socket that is part of the wire harness. Then try to start the engine & see if it runs after start. If it does, then the resistor is your most likely suspect. If it still dies after starting, either the relay is going bad or you still have a fuel issue.

WARNING - Only bypass the resistor for testing. DO NOT DRIVE THE TRUCK WITH THE RESISTOR BYPASSED. Your fuel pump is designed to run on 9.5 volts most of the time. It only gets full battery voltage for very short periods of time, on startup. If you bypass the resistor the pump will be getting full battery voltage all the time, & could burn out the pump or cause other system damage if run this way for an extended period of time.

If it turns out that the resistor is the problem let me know, I have a fix for that & can point you in the right direction. If the resistor checks as totally fine, it may be the relay. I have more info on that as well but since this post is long enough, just ask.

Let us know what you find out.

I think you can forget the coil for now. If it starts while cranking the coil is working. Also means your Ignitor (Ignition Control Module) and Distributor Pickup Coil are working. You shouldn't have a ballast resistor on the coil, those were only used with the earlier "points" distributors. If you want to test the coil with an Ohm Meter anyway, the specs are:

Primary Resistance: 1.3 to 1.7 Ohms

Secondary Resistance: 6500 to 10500 Ohms

Make sure you remove/disconnect all 3 leads to the coil before you test it. If you don't have a "self-zeroing" Ohm Meter, connect the leads together on the 200 Ohms scale to see what the resistance is in the test leads, & subtract this amount from the reading for the Primary Resistance. The extra resistance in the leads doesn't matter that much on the Secondary Resistance reading.

Fuel Pump test - The '77 does have an electric fuel pump in the tank. Have you tested it for fuel flow? I mean a visual verification of fuel flow under certain conditions. I would disconnect the fuel feed line to the carb & put the end in a container to catch any gas, then try to start the engine. There should be enough gas left in the carb to do this. If you get flow while cranking & then flow stops when it starts (key released to "RUN" position) see #2 below. If engine starts & you still get THE SAME* fuel flow when key is released to the "RUN" position, see #1 below. Also remember that your truck is 42 years old & probably needs some attention to the things I am going to outline below. My '78 sure did. BTW, fuel flow on these pumps is about 1 quart (32 ounces) every 15 seconds, or approx. 1 gallon per minute, so make sure your catch container is big enough.

I think you have one of 2 different possible problems:

#1 - FUEL/VACUUM ISSUES - Bad Fuel Filter. Idle Passage(s) partially or completely blocked, Throttle Shaft Bushings worn causing a vacuum leak, small crack(s) in rubber fuel line(s), Loose Fuel Line Clamp(s). You didn't say how old your carb was, when it was rebuilt last, whether you've recently cleaned it or not, how old the fuel filter is, what condition the rubber line are in, whether or not you check clamp tightness, & more. You have to go over all the small stuff BEFORE you try diagnosing or replacing parts.

Loose hose clamps can cause the fuel system to suck in air. Same with small cracks in the rubber lines. You said you "emptied out the fuel filter" & it refilled after a few attempts at cranking, but that doesn't mean that the filter media inside is good. Over time the filter can get partially blocked up causing a restriction. Replace the fuel filter, they are cheap, it's easy to do & will give you one less suspect.

Worn Throttle Shaft Bushings can cause large vacuum leaks in the carb. If you recently EXTERNALLY cleaned the carb this could have removed dirt or grime that was acting like a vacuum seal on the worn shaft bushings. The engine will start cold because the choke is making the mixture rich, or will start hot giving it a little extra gas with the pedal. But once started the vacuum leak leans it out too much & it dies. Check for looseness or "wobble" on the shaft; there should be none if it's good. This is the larger shaft at the base of the carb.

Blocked Idle Passage(s) - I had this problem, and with a freshly pro rebuilt carb too. Turns out the Ethanol blend fuel of today was eating away the insides of my old rubber fuel lines. Tiny particles of rubber clogged up my idle passages in the carb, so the engine would start but not keep running. Another good reason to check & perhaps replace your old fuel lines with Ethanol resistant lines. I fixed the problem by removing the fuel bowl drain bolts, idle cutoff solenoid & mixture screw, so I could get access to the idle passages. Used carb cleaner to spray out the fuel bowl, shoot cleaner through both jets, into the port for the solenoid & the mixture screw hole. The blew it all out with some compressed air then put everything back. it worked. Just had to check how many turns out the mixture screw was before completely removing it, so I could put it back at the right "setting". I also replaced every rubber fuel line on the truck with new, ethanol resistant fuel line, as well as all new clamps

#2 - Issue with the Electrical Circuit for the Fuel Pump. If you get no flow or noticeably reduced flow of fuel when the key is released to the "RUN" position, I would suspect that your Fuel Pump Resistor is the cause. Here is a diagram of the electrical system for the fuel pump:

I will explain the circuit. In looking at the diagram, you'll notice that the fuel pump circuit gets full battery power from the "START" side of the ignition through the Fuel Pump Relay. The relay is energized & switches the "pole" inside the relay to the START side whenever you have low or no oil pressure, thanks to the Oil Pressure Switch. The switch is "closed" at low or no oil pressure & allows voltage to flow to the coil in the relay, and sends voltage to your "OIL" warning light on the dashboard. Once enough oil pressure is built up, the pressure "opens" the switch, turns off the "OIL" light & allows the pole to flop back to the "RUN" side. This brings the resistor into play. The resistor drops the battery voltage to the fuel pump down to about 9.5 volts. This extends the life of the fuel pump & makes it run quieter. The pump is designed to run at this voltage & provide the correct fuel pressure & volume for running conditions.

Over time, the fuel pump resistor, due to exposure to engine heat & who knows how many cycles, will begin to fatigue & change in resistance to a higher level & this only gets worse as it heats up. The higher resistance drops the voltage to a point where there may not be enough voltage to the pump for it to pump properly. My old resistor when hot read more than double it's spec, & my calculations showed the pump was only getting something like 3 volts instead of the usual 9.5 volts(!). This results in little or no fuel flow when the key was in the "RUN" position, & why the engine would not keep running after starting.

First, make sure your fuel pump resistor is still connected & that the contacts in the plug & socket are clean. It is located in top of the passenger side fender well & looks like this:

You can test it with an Ohm Meter like the coil. The spec on it is:

Ceramic Power Resistor, 1.4 Ohms, 10 Watts, 10% Tolerance

Cold, it might read within spec, so it's a good idea to get a hair dryer or heat gun & heat it up some while watching the ohm meter. If it's good, you shouldn't see anything beyond 1.6 Ohms, even when hot (200 F maximum). When I tested mine with a hair dryer it eventually topped out at 2.9 Ohms, more than double the original spec.

You can also test it by bypassing the resistor. Disconnect the green plug & put a jumper wire in the socket that is part of the wire harness. Then try to start the engine & see if it runs after start. If it does, then the resistor is your most likely suspect. If it still dies after starting, either the relay is going bad or you still have a fuel issue.

WARNING - Only bypass the resistor for testing. DO NOT DRIVE THE TRUCK WITH THE RESISTOR BYPASSED. Your fuel pump is designed to run on 9.5 volts most of the time. It only gets full battery voltage for very short periods of time, on startup. If you bypass the resistor the pump will be getting full battery voltage all the time, & could burn out the pump or cause other system damage if run this way for an extended period of time.

If it turns out that the resistor is the problem let me know, I have a fix for that & can point you in the right direction. If the resistor checks as totally fine, it may be the relay. I have more info on that as well but since this post is long enough, just ask.

Let us know what you find out.

The following 3 users liked this post by 13Swords:

#19

I have a '78 that I have been "through the mill" with & I've fixed & redone every system, including ignition & fuel. My research (and it's been TONS) tells me that the '77 & '78 are identical in systems and components.

I think you can forget the coil for now. If it starts while cranking the coil is working. Also means your Ignitor (Ignition Control Module) and Distributor Pickup Coil are working. You shouldn't have a ballast resistor on the coil, those were only used with the earlier "points" distributors. If you want to test the coil with an Ohm Meter anyway, the specs are:

Primary Resistance: 1.3 to 1.7 Ohms

Secondary Resistance: 6500 to 10500 Ohms

Make sure you remove/disconnect all 3 leads to the coil before you test it. If you don't have a "self-zeroing" Ohm Meter, connect the leads together on the 200 Ohms scale to see what the resistance is in the test leads, & subtract this amount from the reading for the Primary Resistance. The extra resistance in the leads doesn't matter that much on the Secondary Resistance reading.

Fuel Pump test - The '77 does have an electric fuel pump in the tank. Have you tested it for fuel flow? I mean a visual verification of fuel flow under certain conditions. I would disconnect the fuel feed line to the carb & put the end in a container to catch any gas, then try to start the engine. There should be enough gas left in the carb to do this. If you get flow while cranking & then flow stops when it starts (key released to "RUN" position) see #2 below. If engine starts & you still get THE SAME* fuel flow when key is released to the "RUN" position, see #1 below. Also remember that your truck is 42 years old & probably needs some attention to the things I am going to outline below. My '78 sure did. BTW, fuel flow on these pumps is about 1 quart (32 ounces) every 15 seconds, or approx. 1 gallon per minute, so make sure your catch container is big enough.

I think you have one of 2 different possible problems:

#1 - FUEL/VACUUM ISSUES - Bad Fuel Filter. Idle Passage(s) partially or completely blocked, Throttle Shaft Bushings worn causing a vacuum leak, small crack(s) in rubber fuel line(s), Loose Fuel Line Clamp(s). You didn't say how old your carb was, when it was rebuilt last, whether you've recently cleaned it or not, how old the fuel filter is, what condition the rubber line are in, whether or not you check clamp tightness, & more. You have to go over all the small stuff BEFORE you try diagnosing or replacing parts.

Loose hose clamps can cause the fuel system to suck in air. Same with small cracks in the rubber lines. You said you "emptied out the fuel filter" & it refilled after a few attempts at cranking, but that doesn't mean that the filter media inside is good. Over time the filter can get partially blocked up causing a restriction. Replace the fuel filter, they are cheap, it's easy to do & will give you one less suspect.

Worn Throttle Shaft Bushings can cause large vacuum leaks in the carb. If you recently EXTERNALLY cleaned the carb this could have removed dirt or grime that was acting like a vacuum seal on the worn shaft bushings. The engine will start cold because the choke is making the mixture rich, or will start hot giving it a little extra gas with the pedal. But once started the vacuum leak leans it out too much & it dies. Check for looseness or "wobble" on the shaft; there should be none if it's good. This is the larger shaft at the base of the carb.

Blocked Idle Passage(s) - I had this problem, and with a freshly pro rebuilt carb too. Turns out the Ethanol blend fuel of today was eating away the insides of my old rubber fuel lines. Tiny particles of rubber clogged up my idle passages in the carb, so the engine would start but not keep running. Another good reason to check & perhaps replace your old fuel lines with Ethanol resistant lines. I fixed the problem by removing the fuel bowl drain bolts, idle cutoff solenoid & mixture screw, so I could get access to the idle passages. Used carb cleaner to spray out the fuel bowl, shoot cleaner through both jets, into the port for the solenoid & the mixture screw hole. The blew it all out with some compressed air then put everything back. it worked. Just had to check how many turns out the mixture screw was before completely removing it, so I could put it back at the right "setting". I also replaced every rubber fuel line on the truck with new, ethanol resistant fuel line, as well as all new clamps

#2 - Issue with the Electrical Circuit for the Fuel Pump. If you get no flow or noticeably reduced flow of fuel when the key is released to the "RUN" position, I would suspect that your Fuel Pump Resistor is the cause. Here is a diagram of the electrical system for the fuel pump:

I will explain the circuit. In looking at the diagram, you'll notice that the fuel pump circuit gets full battery power from the "START" side of the ignition through the Fuel Pump Relay. The relay is energized & switches the "pole" inside the relay to the START side whenever you have low or no oil pressure, thanks to the Oil Pressure Switch. The switch is "closed" at low or no oil pressure & allows voltage to flow to the coil in the relay, and sends voltage to your "OIL" warning light on the dashboard. Once enough oil pressure is built up, the pressure "opens" the switch, turns off the "OIL" light & allows the pole to flop back to the "RUN" side. This brings the resistor into play. The resistor drops the battery voltage to the fuel pump down to about 9.5 volts. This extends the life of the fuel pump & makes it run quieter. The pump is designed to run at this voltage & provide the correct fuel pressure & volume for running conditions.

Over time, the fuel pump resistor, due to exposure to engine heat & who knows how many cycles, will begin to fatigue & change in resistance to a higher level & this only gets worse as it heats up. The higher resistance drops the voltage to a point where there may not be enough voltage to the pump for it to pump properly. My old resistor when hot read more than double it's spec, & my calculations showed the pump was only getting something like 3 volts instead of the usual 9.5 volts(!). This results in little or no fuel flow when the key was in the "RUN" position, & why the engine would not keep running after starting.

First, make sure your fuel pump resistor is still connected & that the contacts in the plug & socket are clean. It is located in top of the passenger side fender well & looks like this:

You can test it with an Ohm Meter like the coil. The spec on it is:

Ceramic Power Resistor, 1.4 Ohms, 10 Watts, 10% Tolerance

Cold, it might read within spec, so it's a good idea to get a hair dryer or heat gun & heat it up some while watching the ohm meter. If it's good, you shouldn't see anything beyond 1.6 Ohms, even when hot (200 F maximum). When I tested mine with a hair dryer it eventually topped out at 2.9 Ohms, more than double the original spec.

You can also test it by bypassing the resistor. Disconnect the green plug & put a jumper wire in the socket that is part of the wire harness. Then try to start the engine & see if it runs after start. If it does, then the resistor is your most likely suspect. If it still dies after starting, either the relay is going bad or you still have a fuel issue.

WARNING - Only bypass the resistor for testing. DO NOT DRIVE THE TRUCK WITH THE RESISTOR BYPASSED. Your fuel pump is designed to run on 9.5 volts most of the time. It only gets full battery voltage for very short periods of time, on startup. If you bypass the resistor the pump will be getting full battery voltage all the time, & could burn out the pump or cause other system damage if run this way for an extended period of time.

If it turns out that the resistor is the problem let me know, I have a fix for that & can point you in the right direction. If the resistor checks as totally fine, it may be the relay. I have more info on that as well but since this post is long enough, just ask.

Let us know what you find out.

I think you can forget the coil for now. If it starts while cranking the coil is working. Also means your Ignitor (Ignition Control Module) and Distributor Pickup Coil are working. You shouldn't have a ballast resistor on the coil, those were only used with the earlier "points" distributors. If you want to test the coil with an Ohm Meter anyway, the specs are:

Primary Resistance: 1.3 to 1.7 Ohms

Secondary Resistance: 6500 to 10500 Ohms

Make sure you remove/disconnect all 3 leads to the coil before you test it. If you don't have a "self-zeroing" Ohm Meter, connect the leads together on the 200 Ohms scale to see what the resistance is in the test leads, & subtract this amount from the reading for the Primary Resistance. The extra resistance in the leads doesn't matter that much on the Secondary Resistance reading.

Fuel Pump test - The '77 does have an electric fuel pump in the tank. Have you tested it for fuel flow? I mean a visual verification of fuel flow under certain conditions. I would disconnect the fuel feed line to the carb & put the end in a container to catch any gas, then try to start the engine. There should be enough gas left in the carb to do this. If you get flow while cranking & then flow stops when it starts (key released to "RUN" position) see #2 below. If engine starts & you still get THE SAME* fuel flow when key is released to the "RUN" position, see #1 below. Also remember that your truck is 42 years old & probably needs some attention to the things I am going to outline below. My '78 sure did. BTW, fuel flow on these pumps is about 1 quart (32 ounces) every 15 seconds, or approx. 1 gallon per minute, so make sure your catch container is big enough.

I think you have one of 2 different possible problems:

#1 - FUEL/VACUUM ISSUES - Bad Fuel Filter. Idle Passage(s) partially or completely blocked, Throttle Shaft Bushings worn causing a vacuum leak, small crack(s) in rubber fuel line(s), Loose Fuel Line Clamp(s). You didn't say how old your carb was, when it was rebuilt last, whether you've recently cleaned it or not, how old the fuel filter is, what condition the rubber line are in, whether or not you check clamp tightness, & more. You have to go over all the small stuff BEFORE you try diagnosing or replacing parts.

Loose hose clamps can cause the fuel system to suck in air. Same with small cracks in the rubber lines. You said you "emptied out the fuel filter" & it refilled after a few attempts at cranking, but that doesn't mean that the filter media inside is good. Over time the filter can get partially blocked up causing a restriction. Replace the fuel filter, they are cheap, it's easy to do & will give you one less suspect.

Worn Throttle Shaft Bushings can cause large vacuum leaks in the carb. If you recently EXTERNALLY cleaned the carb this could have removed dirt or grime that was acting like a vacuum seal on the worn shaft bushings. The engine will start cold because the choke is making the mixture rich, or will start hot giving it a little extra gas with the pedal. But once started the vacuum leak leans it out too much & it dies. Check for looseness or "wobble" on the shaft; there should be none if it's good. This is the larger shaft at the base of the carb.

Blocked Idle Passage(s) - I had this problem, and with a freshly pro rebuilt carb too. Turns out the Ethanol blend fuel of today was eating away the insides of my old rubber fuel lines. Tiny particles of rubber clogged up my idle passages in the carb, so the engine would start but not keep running. Another good reason to check & perhaps replace your old fuel lines with Ethanol resistant lines. I fixed the problem by removing the fuel bowl drain bolts, idle cutoff solenoid & mixture screw, so I could get access to the idle passages. Used carb cleaner to spray out the fuel bowl, shoot cleaner through both jets, into the port for the solenoid & the mixture screw hole. The blew it all out with some compressed air then put everything back. it worked. Just had to check how many turns out the mixture screw was before completely removing it, so I could put it back at the right "setting". I also replaced every rubber fuel line on the truck with new, ethanol resistant fuel line, as well as all new clamps

#2 - Issue with the Electrical Circuit for the Fuel Pump. If you get no flow or noticeably reduced flow of fuel when the key is released to the "RUN" position, I would suspect that your Fuel Pump Resistor is the cause. Here is a diagram of the electrical system for the fuel pump:

I will explain the circuit. In looking at the diagram, you'll notice that the fuel pump circuit gets full battery power from the "START" side of the ignition through the Fuel Pump Relay. The relay is energized & switches the "pole" inside the relay to the START side whenever you have low or no oil pressure, thanks to the Oil Pressure Switch. The switch is "closed" at low or no oil pressure & allows voltage to flow to the coil in the relay, and sends voltage to your "OIL" warning light on the dashboard. Once enough oil pressure is built up, the pressure "opens" the switch, turns off the "OIL" light & allows the pole to flop back to the "RUN" side. This brings the resistor into play. The resistor drops the battery voltage to the fuel pump down to about 9.5 volts. This extends the life of the fuel pump & makes it run quieter. The pump is designed to run at this voltage & provide the correct fuel pressure & volume for running conditions.

Over time, the fuel pump resistor, due to exposure to engine heat & who knows how many cycles, will begin to fatigue & change in resistance to a higher level & this only gets worse as it heats up. The higher resistance drops the voltage to a point where there may not be enough voltage to the pump for it to pump properly. My old resistor when hot read more than double it's spec, & my calculations showed the pump was only getting something like 3 volts instead of the usual 9.5 volts(!). This results in little or no fuel flow when the key was in the "RUN" position, & why the engine would not keep running after starting.

First, make sure your fuel pump resistor is still connected & that the contacts in the plug & socket are clean. It is located in top of the passenger side fender well & looks like this:

You can test it with an Ohm Meter like the coil. The spec on it is:

Ceramic Power Resistor, 1.4 Ohms, 10 Watts, 10% Tolerance

Cold, it might read within spec, so it's a good idea to get a hair dryer or heat gun & heat it up some while watching the ohm meter. If it's good, you shouldn't see anything beyond 1.6 Ohms, even when hot (200 F maximum). When I tested mine with a hair dryer it eventually topped out at 2.9 Ohms, more than double the original spec.

You can also test it by bypassing the resistor. Disconnect the green plug & put a jumper wire in the socket that is part of the wire harness. Then try to start the engine & see if it runs after start. If it does, then the resistor is your most likely suspect. If it still dies after starting, either the relay is going bad or you still have a fuel issue.

WARNING - Only bypass the resistor for testing. DO NOT DRIVE THE TRUCK WITH THE RESISTOR BYPASSED. Your fuel pump is designed to run on 9.5 volts most of the time. It only gets full battery voltage for very short periods of time, on startup. If you bypass the resistor the pump will be getting full battery voltage all the time, & could burn out the pump or cause other system damage if run this way for an extended period of time.

If it turns out that the resistor is the problem let me know, I have a fix for that & can point you in the right direction. If the resistor checks as totally fine, it may be the relay. I have more info on that as well but since this post is long enough, just ask.

Let us know what you find out.

The pickup is a 76 Chinook. Also, disclaimer, I have close to zero mechanical and electrical experience but I am following you..with a little bit of struggle.

I moved forward with #2 because on -start- it seems to be getting plenty of fuel and turns over fine. I did change the fuel filter and visually tested fuel flow into a container when starting.

With a meter it tested 1.4 and also didn't start with a jumper wire. Can you tell me more about the relay?

Thanks again!

#20

Registered User

No problem, glad to pass along what I have learned about these systems. The '76 is the same; all '75 to '78 models have exactly the same fuel systems in them. No worries about the "zero knowledge." If you're willing you can always learn as you go; I did!

You say it seems to be getting plenty of fuel on "START" but you didn't mention the "RUN" side of things. I am assuming that you aren't getting fuel flow on "RUN"? If so, that would mean that the contact in the relay on the "RUN" side has some problems, like the contacts being pitted, burned or corroded. If the relay is original to the truck it's very likely that the "RUN" contact is just plain worn out. The contacts pitting/corroding is caused by electric arcing when the contacts close or open. Over time, the arcing can literally "eat away" the metal, leaving a pitted surface that does not conduct electricity very well, and sometimes not at all. Just Google search "pitted relay contacts" & checks the Images, you'll see what this looks like.

Your fuel pump relay should be located under the center of the dash and if original, will have a metal cover on it. The original Toyota Part # is 28380-20010, Nippon Denso Part # 056700-3640. The only exact replacement I can find is $80+ here: https://www.toyotapartsdeal.com/oem/...=RN80L-TRLDSA)

There is a later version that MIGHT work in the circuit, that is listed as for 22R carbureted models 1983 to 1987 here: https://www.rockauto.com/en/catalog/...ing+relay,3380

From what I can tell, those model years are wired the same, through the Oil Pressure Switch, so it might work the same. I say "MIGHT" work because I have not tried this part myself on a '75 to '78. However since it's for a carb system and not the fuel injection model, I think it might work.

The other alternative (as I am cheap AND broke) is to do what I did & replace the relay with a Bosch style relay & pigtail socket like this:

The Bosch style relay operates in the same electrical way as the Toyota relay. The only difference is the layout of the spade lugs on the relays. The relay has to be rated for 12 volts & 30/40 Amps, as shown in the example (in fact this is the exact relay I used). I bought an assortment of spade lugs & shrink tubing from Harbor Freight. I crimped on the right size female lugs that would fit on the male terminal lugs in the relay socket on the truck's wiring harness & shrink tubed the connections for insulation. This way I didn't have to hack off the old socket & kept it original, in case I ever could afford the new, expensive Toyota Relay. Then it was just a matter of connecting the correct wires to the correct terminals & mounting up the relay. I did have to drill out the mounting hole in the tab a bit to get it to fit.

I do have a video on this on Youtube in which I try to explain how this all works, and I did include some diagrams near the end of the video, which you can pause the video on & take notes. Link:

My apologies in advance for all the rambling; I need a script! :^) I have been running the truck on this relay setup for 3 years now & it works perfectly. Any questions on this let me know.

You say it seems to be getting plenty of fuel on "START" but you didn't mention the "RUN" side of things. I am assuming that you aren't getting fuel flow on "RUN"? If so, that would mean that the contact in the relay on the "RUN" side has some problems, like the contacts being pitted, burned or corroded. If the relay is original to the truck it's very likely that the "RUN" contact is just plain worn out. The contacts pitting/corroding is caused by electric arcing when the contacts close or open. Over time, the arcing can literally "eat away" the metal, leaving a pitted surface that does not conduct electricity very well, and sometimes not at all. Just Google search "pitted relay contacts" & checks the Images, you'll see what this looks like.

Your fuel pump relay should be located under the center of the dash and if original, will have a metal cover on it. The original Toyota Part # is 28380-20010, Nippon Denso Part # 056700-3640. The only exact replacement I can find is $80+ here: https://www.toyotapartsdeal.com/oem/...=RN80L-TRLDSA)

There is a later version that MIGHT work in the circuit, that is listed as for 22R carbureted models 1983 to 1987 here: https://www.rockauto.com/en/catalog/...ing+relay,3380

From what I can tell, those model years are wired the same, through the Oil Pressure Switch, so it might work the same. I say "MIGHT" work because I have not tried this part myself on a '75 to '78. However since it's for a carb system and not the fuel injection model, I think it might work.

The other alternative (as I am cheap AND broke) is to do what I did & replace the relay with a Bosch style relay & pigtail socket like this:

The Bosch style relay operates in the same electrical way as the Toyota relay. The only difference is the layout of the spade lugs on the relays. The relay has to be rated for 12 volts & 30/40 Amps, as shown in the example (in fact this is the exact relay I used). I bought an assortment of spade lugs & shrink tubing from Harbor Freight. I crimped on the right size female lugs that would fit on the male terminal lugs in the relay socket on the truck's wiring harness & shrink tubed the connections for insulation. This way I didn't have to hack off the old socket & kept it original, in case I ever could afford the new, expensive Toyota Relay. Then it was just a matter of connecting the correct wires to the correct terminals & mounting up the relay. I did have to drill out the mounting hole in the tab a bit to get it to fit.

I do have a video on this on Youtube in which I try to explain how this all works, and I did include some diagrams near the end of the video, which you can pause the video on & take notes. Link: